最終更新日: 2025年4月7日

LIMEX Sheet

炭酸カルシウム(石灰石)などを主原料とするLIMEX Sheet(ライメックスシート)は、プラスチックや紙の代替として使用することが可能な素材です。石油由来プラスチックで成形されたシートと比較し、石油由来プラスチック使用量を削減することができます。また、紙に比べて、製造時に水をほぼ使用せず、耐久性と耐水性に優れており、屋内外での利用が可能です。LIMEX Sheetは、実質「100%再生可能エネルギー由来」「CO₂排出係数ゼロ」の電力を使用している、自社製造拠点である宮城県の「東北LIMEX工場」で製造されています。

石油由来プラスチックシートの

代替として

「LIMEX Sheet」は、従来の石油由来プラスチック製シートに比べ、石油の使用量を大幅に削減できます。そのため、限りある石油資源の保全に貢献でき、原材料の調達から処分までのライフサイクル全体でCO₂排出量も抑えることが可能です。主原料の石灰石は石油由来プラスチックと比較し、供給安定性が優れており、価格の変動が少ないため、安定した価格での提供が可能です。

製品のライフサイクルで生じる環境影響については、LCA(ライフサイクルアセスメント)を通して環境影響の可視化とその抑制に取り組んでいます。ここでは、各種石油由来プラスチックと比較した環境性能について、製品のライフサイクル全体(原料調達段階から処分)を通じてのCO₂等の温室効果ガス(GHG)排出量やプラスチックの使用量といった詳細データによって具体的にお示します。

• インベントリデータベース(排出原単位の主な参照先) :LCIデータベースIDEA version 2.3 (2019/12/27)、国⽴研究開発法⼈産業技術総合研究所安全科学研究部⾨IDEAラボ、⼀般社団法⼈サステナブル経営推進機構(SuMPO)

• 影響評価⼿法:Climate change IPCC 2013 GWP 100a

他社製品との比較はできません。|特定の製造条件を満たして製造された場合の計算値であり保証値ではありません。|プラスチック削減量の値には製造時のロスは含みません。

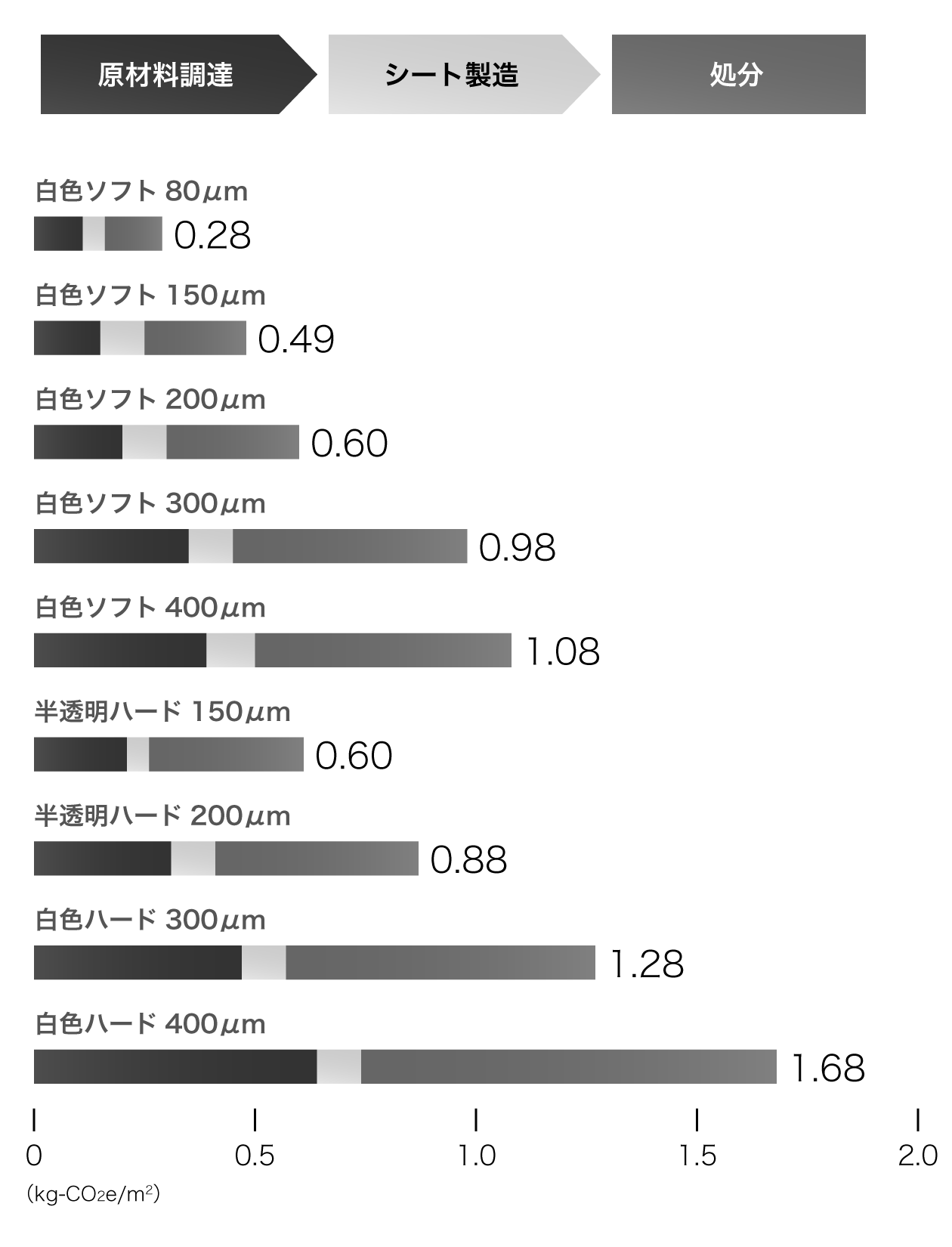

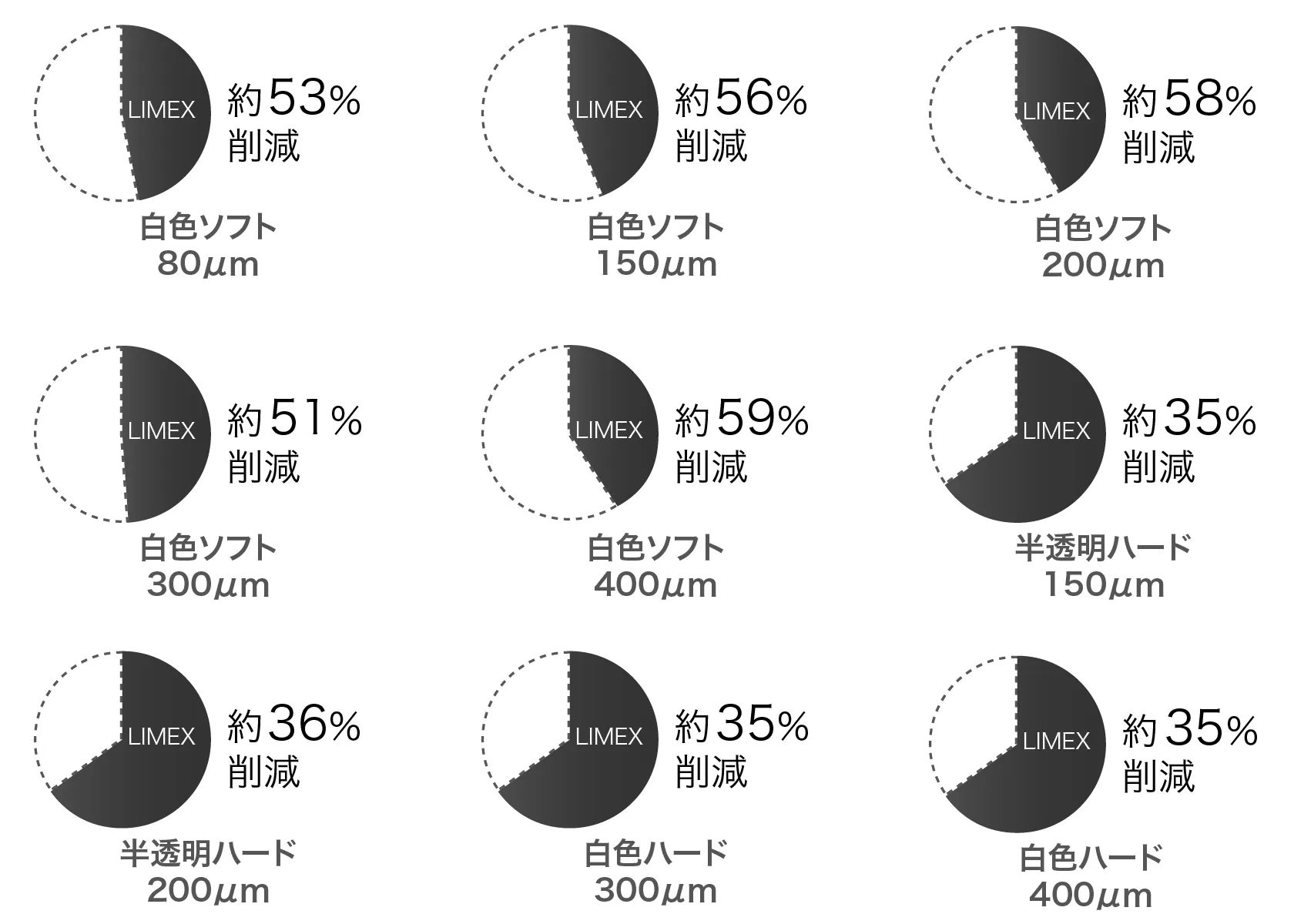

LIMEX Sheetの環境性能

LIMEX Sheetは冊子やチラシなどに適した80μmからメニュー表などに用いられる400μmまで、多様な厚みや硬さの製品をラインナップしています。各製品のライフサイクル(原料調達段階から処分)を通じてのGHG排出量やプラスチックの削減量は以下の通りです。

GHG排出量

• 機能単位:シート 1㎡

• スコープ:[原材料調達]〜[シート製造]〜[処分]

• 処分:⼀般廃棄物として焼却を想定

※製造条件、80μmは2021年のTBM多賀城工場での試作条件に、それ以外は2020年度のTBM⽩⽯⼯場の実績に基づく

※印刷に適した塗⼯が施されている想定

• LIMEX Sheet:実質100%再⽣可能エネルギー由来の電⼒を使⽤

• 他のプラスチック製シート:⽇本の平均的な電⼒を使⽤した想定

石油由来プラスチック削減量

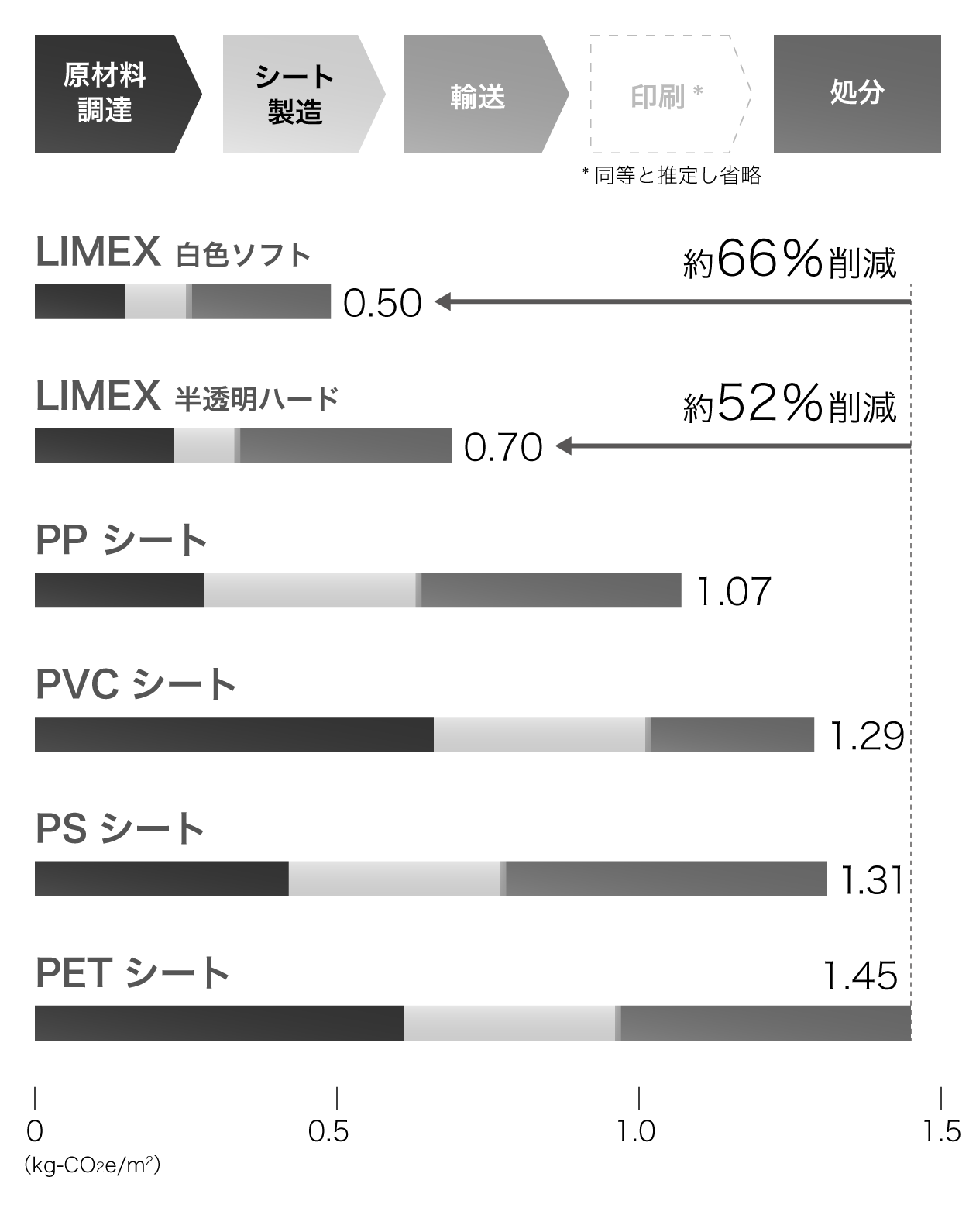

石油由来プラスチックシート、

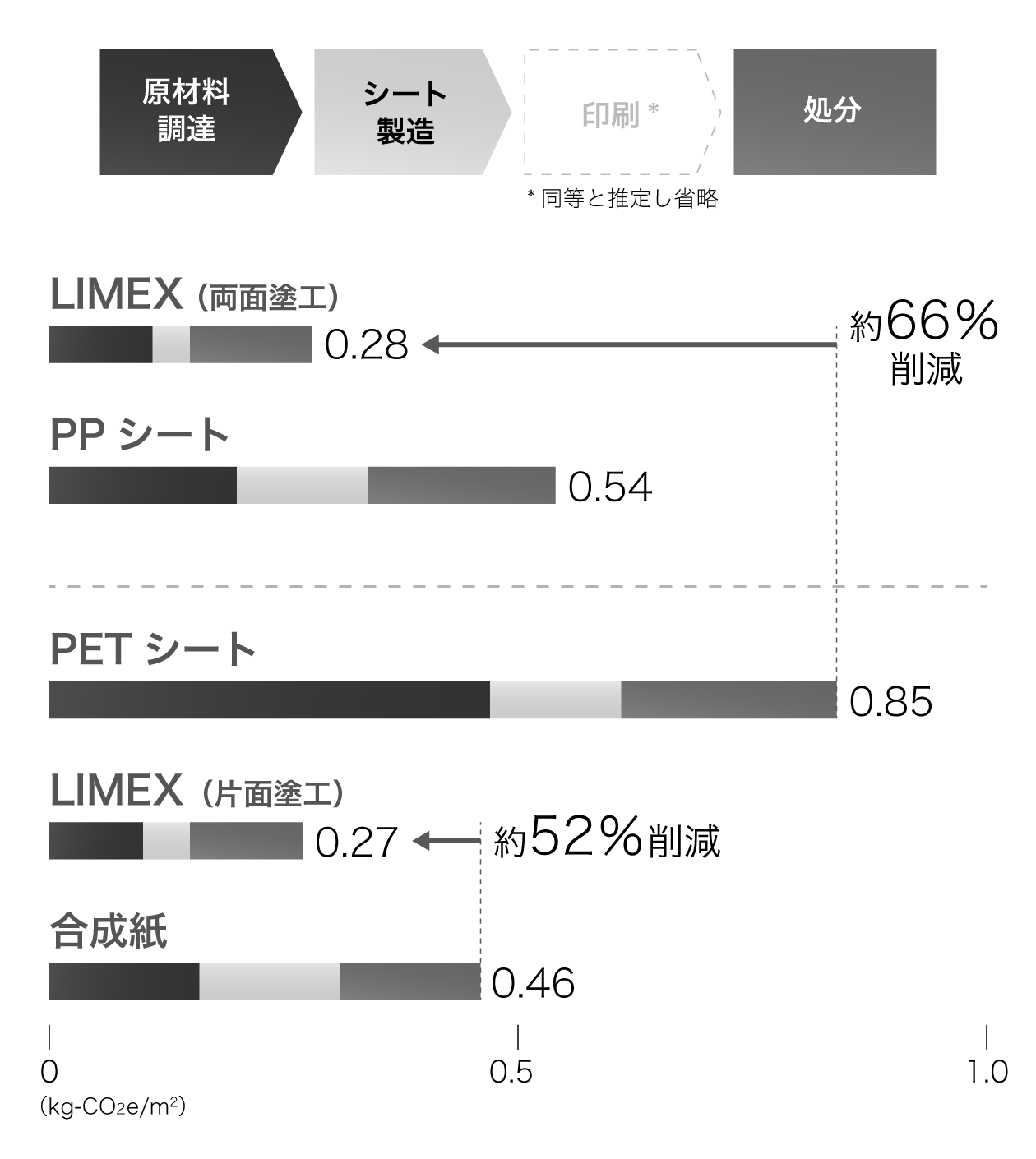

合成紙代替としての環境性能

LIMEX Sheetは、従来から使用されている石油由来プラスチック製のシートや、石油由来プラスチックを主原料とする合成紙に比べ、温室効果ガス排出量を抑え、プラスチックの使用量も減らせます。

150µm

GHG排出量

• 機能単位:シート 1㎡

• スコープ:[原材料調達]~[シート製造]~[輸送]~[処分(焼却)]

• 処分:一般廃棄物として焼却を想定

※製造条件は2020年度のTBM白石工場の実績に基づく

※印刷に適した塗工が施されている想定

• LIMEX Sheet:実質100%再生可能エネルギー由来の電力を使用

• 他のプラスチック製シート:日本の平均的な電力を使用した想定

• 算定年:2021年

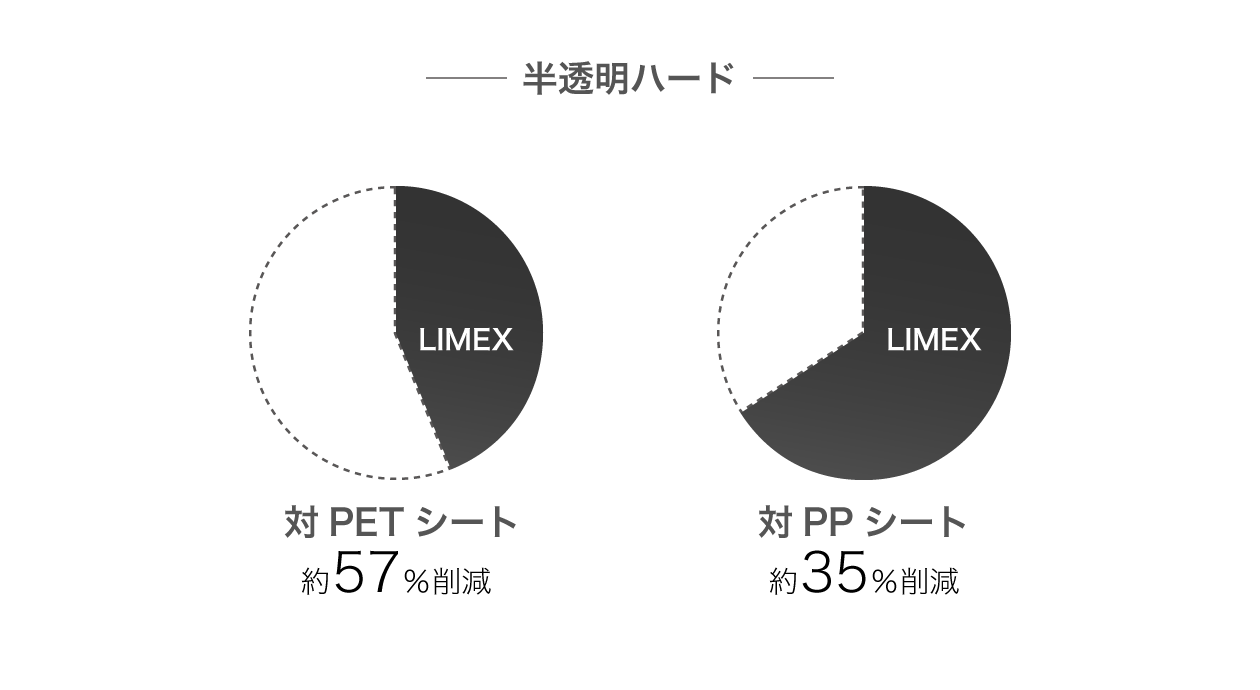

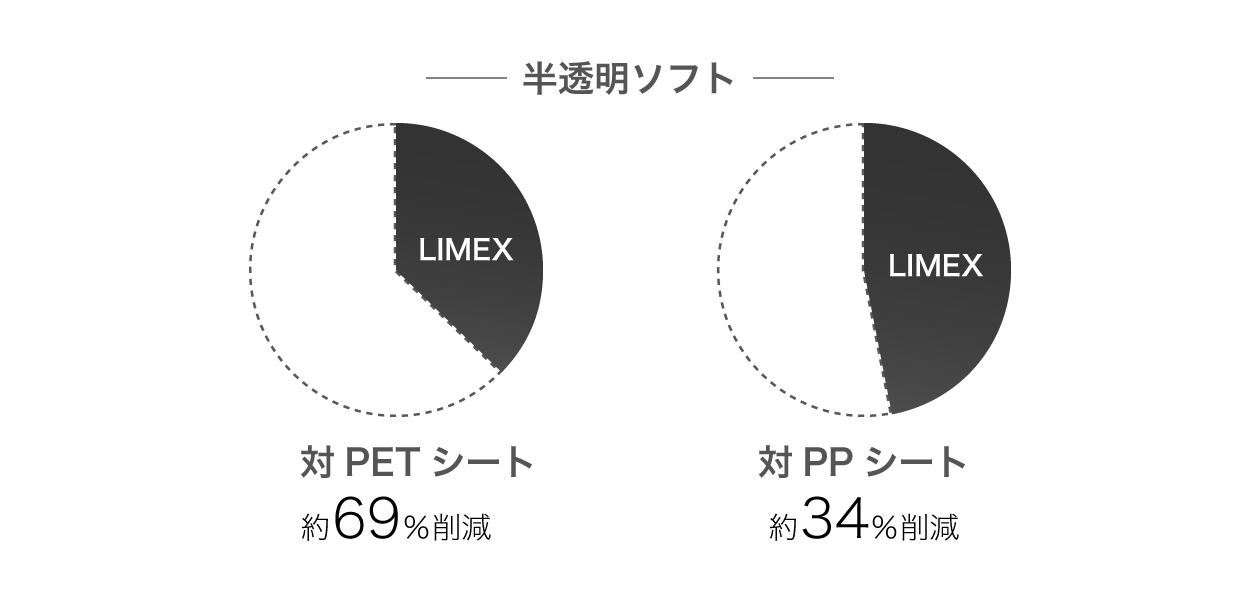

石油由来プラスチック削減量

80µm

GHG排出量

• 機能単位:シート 1 ㎡

• 合成紙はPPを主原料に炭酸カルシウム比率26.2%を想定

• スコープ:[原材料調達]~[シート製造]~[処分(焼却)]

• 処分:一般廃棄物として焼却を想定

※製造条件は2021年のTBM多賀城工場での試作条件に基づく

※印刷に適した塗工が施されている想定

• LIMEX Sheet:実質100%再生可能エネルギー由来の電力を使用

• 他のプラスチック製シート・合成紙:日本の平均的な電力を使用した想定

• 算定年:2022年

石油由来プラスチック削減量

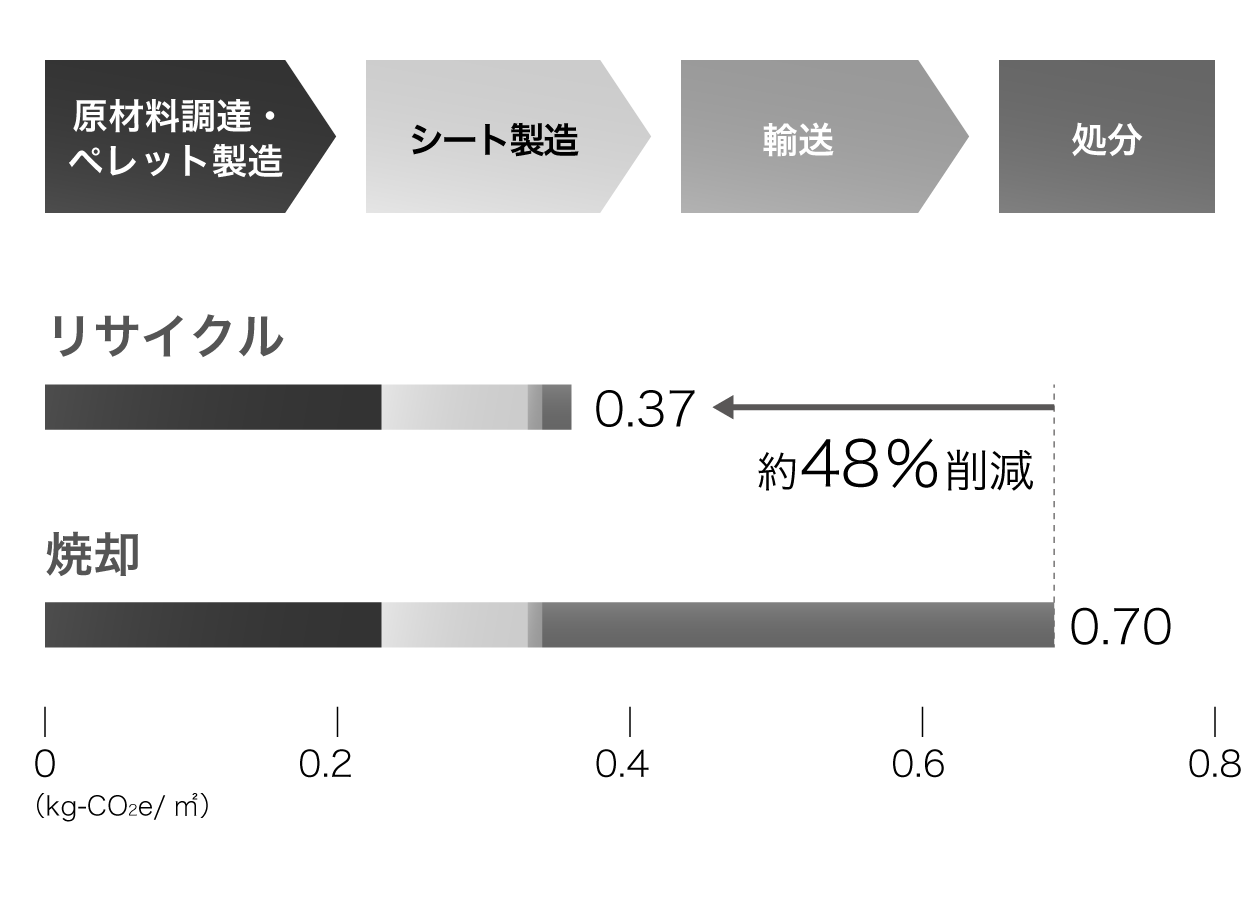

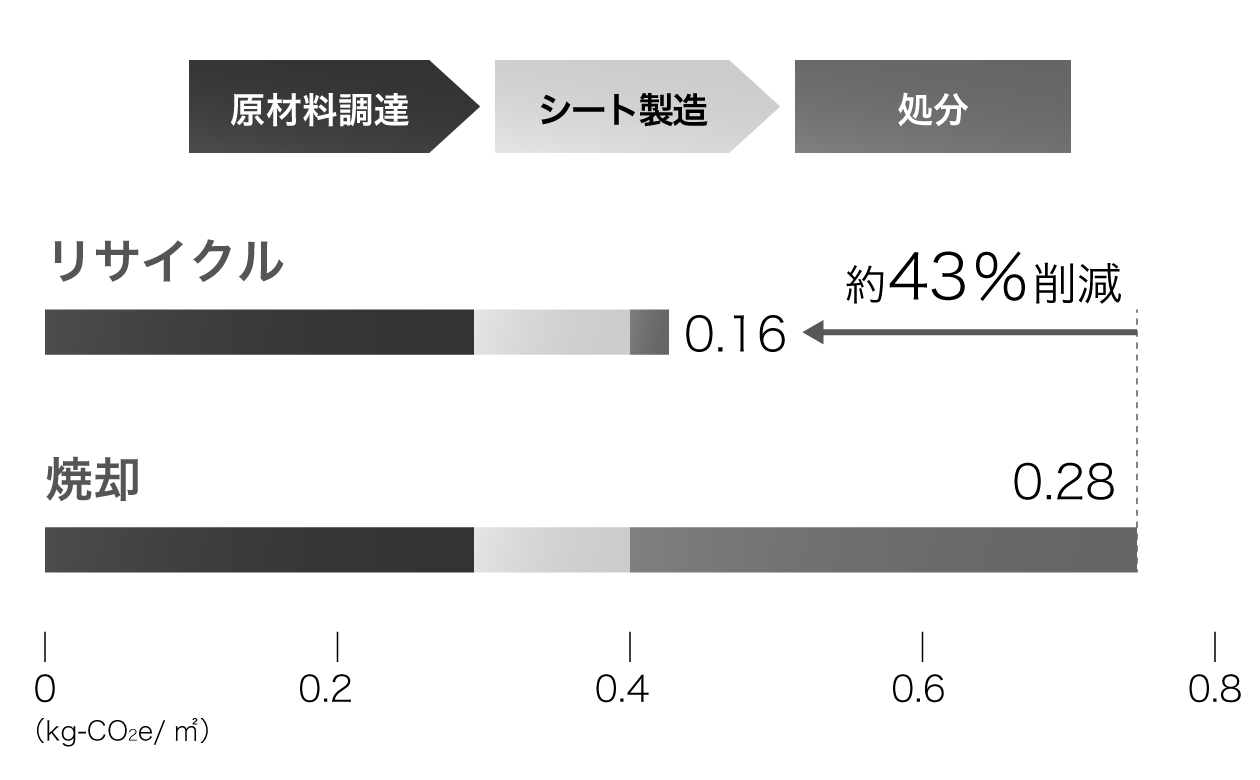

リサイクルによるGHG排出量の低減

LIMEX製品のライフサイクルを通じたGHG排出量は、焼却処分ではなくマテリアルリサイクルすることで大幅に削減することができます。TBMは、自社運営のリサイクルプラントを運営するなど、LIMEXの資源循環にも取り組んでいます。

150µmハード

GHG排出量

80µmソフト

GHG排出量

• 機能単位:シート 1㎡

• スコープ:150μm製品は[原材料調達]~[シート製造]~[輸送]~[処分] 80μm製品は[原材料調達]~[シート製造]~[処分]

• 処分:一般廃棄物として焼却を想定

• リサイクル:ベール化されることを想定

※150μm製品は製造条件は2020年度のTBM白石工場の実績に、80μm製品は2021年のTBM多賀城工場での試作条件に基づく

※印刷に適した塗工が施されている想定

• 実質100%再生可能エネルギー由来の電力を使用

• 算定年: 150μm製品は2021年、 80μm製品は2022年

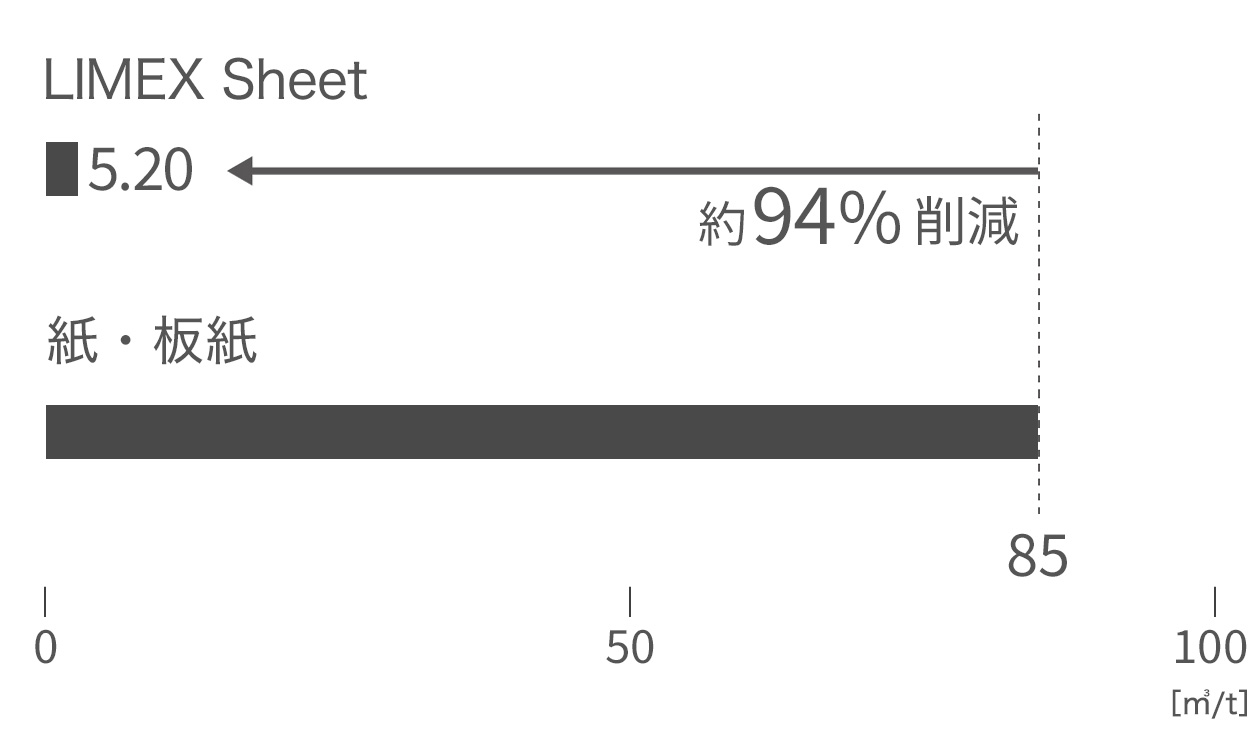

紙の代替として

「LIMEX Sheet」は、製造工程で水資源をほとんど使用せず、森林資源を用いないため、枯渇リスクの高い資源の保全に貢献しています。耐水性に優れており、一般的な紙製のポスターと比較して破れにくい特徴があります。また、メニュー表や POP など、ラミネート加工された印刷物のように紙とプラスチックを分離し、処理する必要がありません。

LIMEX Sheet製品は、単一素材で設計された製品と同様にリサイクルが容易であり、 事業者・消費者・自治体と連携したマテリアルリサイクルの事例が数多くあります。LIMEX Sheet製品は可燃で焼却処理も可能ですが、廃棄物として処分するのではなく、資源として再生していく取り組みを進めています。

紙と比べて水利用量を低減

LIMEXは、製造時に水をほぼ使う必要がありません。LIMEX Sheetは、シート1トンあたりの工場における水利用量を紙と比較し約94%削減できます。

(出典)紙・板紙生産トン当たりの新水利用原単位の推移:日本製紙連合会

(出典)東北LIMEX工場での水利用量を生産量で除した値:2025年1月 TBM調べ

※LIMEX Sheet:150μm以上の厚みの品番

LIMEX Sheetの品番・特徴・用途例

UVオフセット・油性オフセット*1、LBP*2、デジタル印刷、インクジェットにご利用いただけます。

*2 80µm、150µmの機種対応についてはお問い合わせください

- 白色・ソフト

- しなやかで白色度が高く、比重の小さいタイプ

| 形態 | 厚み | 主な用途 |

|---|---|---|

| 枚葉 | 80μm | 冊子、チラシ、マップ |

| 枚葉 | 150μm | ポスター、冊子、チラシ、パンフレット、POP、マップ |

| 枚葉 | 200µm | ポスター、冊子、チラシ、パンフレット、POP |

| 枚葉 | 300µm | 名刺、メニュー表、折箱、POP |

| 枚葉 | 400µm | 名刺、メニュー表、折箱、タペストリー、POP |

| ロール | 150μm | ポスター、冊子、チラシ、パンフレット、POP、マップ |

| ロール | 200μm | ポスター、冊子、チラシ、パンフレット、POP |

| ロール | 300µm | 名刺、メニュー表、折箱、POP |

- 半透明・ハード

- 半透明でコシが強いタイプ

| 形態 | 厚み | 主な用途 |

|---|---|---|

| 枚葉 | 150μm | クリアファイル、マスクケース、電飾フィルム、折箱(組箱)

|

| 枚葉 | 200μm | クリアファイル、マスクケース、電飾フィルム、折箱(組箱) |

| 枚葉 | 300µm | クリアファイル、マスクケース、電飾フィルム、折箱(組箱) |

- 白色・ハード

- 白色度の高さとコシの強さを両立

| 形態 | 厚み | 主な用途 |

|---|---|---|

| 枚葉 | 300μm | メニュー表、パッケージ、ドアタグ、POP、うちわ、カレンダー(卓上)

|

| 枚葉 | 400μm | メニュー表、パッケージ、ドアタグ、POP、うちわ、カレンダー(卓上) |