資源循環事業

資源がめぐる工場を、アップデートする。

国内で排出される廃プラスチックの処理は焼却に大きく依存し、高品質な再生材の安定供給が難しい状況に対し、当社は最新自動選別技術による国内最大級のプラスチックのマテリアルリサイクルプラントを運営することで、家庭由来の容器包装プラスチック(PCR)から、高品質な容器包装リサイクル材(容リ材)を製造しています。動脈産業である素材開発で培った独自の開発技術とR&D機能を活かし、従来の容リ材が抱えていた臭気や物性低下といった課題を解決するだけでなく、PIR(産業廃棄物由来プラスチック)やバージン材と同等以上の強度も一部可能となりました。また、市場に出回る高品質な再生材の、品質や透明性を担保した形での売買をサポート。これにより品質に妥協しない企業の安心した再生材調達を促進し、社会の資源循環並びに、マテリアルリサイクルを通じたCO₂削減による脱炭素化に貢献します。

事業を取り巻く環境と課題

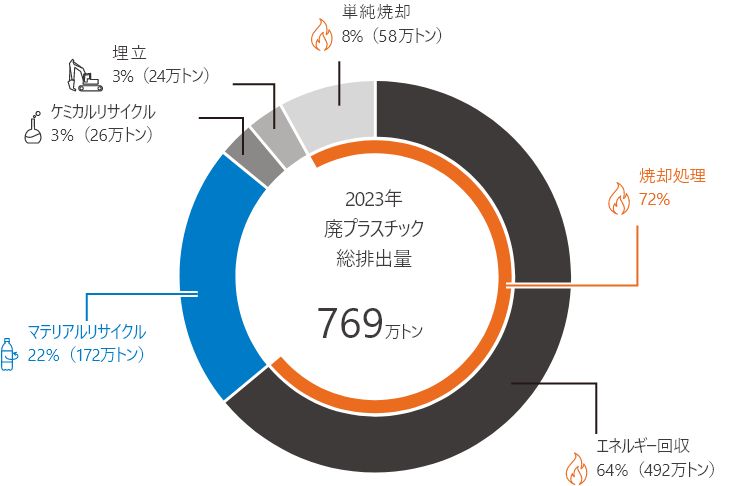

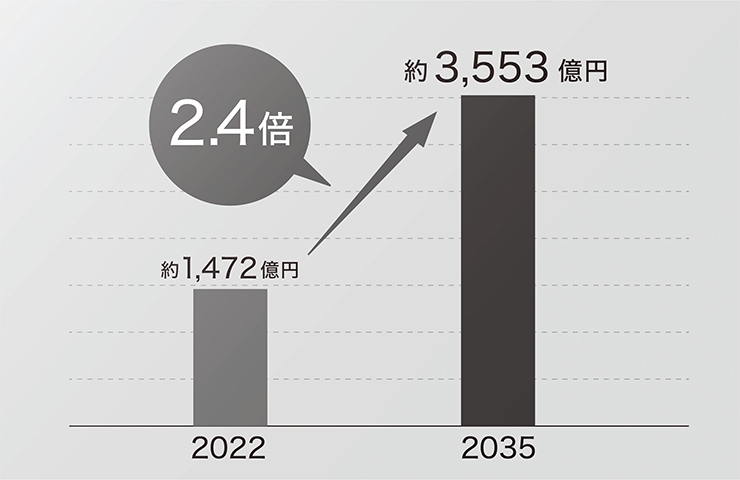

循環型社会の実現が世界的に求められる中、国内で排出される年間769万トンの廃プラスチックのうち、マテリアルリサイクルされるのは僅か22%であり、約7割のプラスチックが焼却処理されています。しかし、国際的な規制強化や国内政策により、焼却に依存しない資源循環モデル、特に焼却と比較してCO₂の排出を抑え、資源の再生が可能なマテリアルリサイクルの推進が強く求められています。同時に、国内の再生プラスチック市場が急成長しており、2035年には約3500億円規模に達する見込みです。このような環境下において、品質の安定したPIR(産業廃棄物由来プラスチック)は需要に対して供給が圧倒的に不足しており、価格や調達難易度が高まっています。対して、家庭から排出される容リ材(PCR)は比較的低価格であるものの、品質のバラつきや臭気、強度不足が再利用の障壁となっていました。当社は、動脈産業である素材開発で培った独自の技術、プロセス改善によりPCRの課題である臭気や強度不足を劇的に改善。PIRやバージン材に依存しない高品質な容リ材の安定供給を実現し、企業の再生材利用と製品品質の両立をサポートしていきます。

プラスチックの大半が焼却、

求められるマテリアルリサイクル

日本の再生プラスチック市場規模

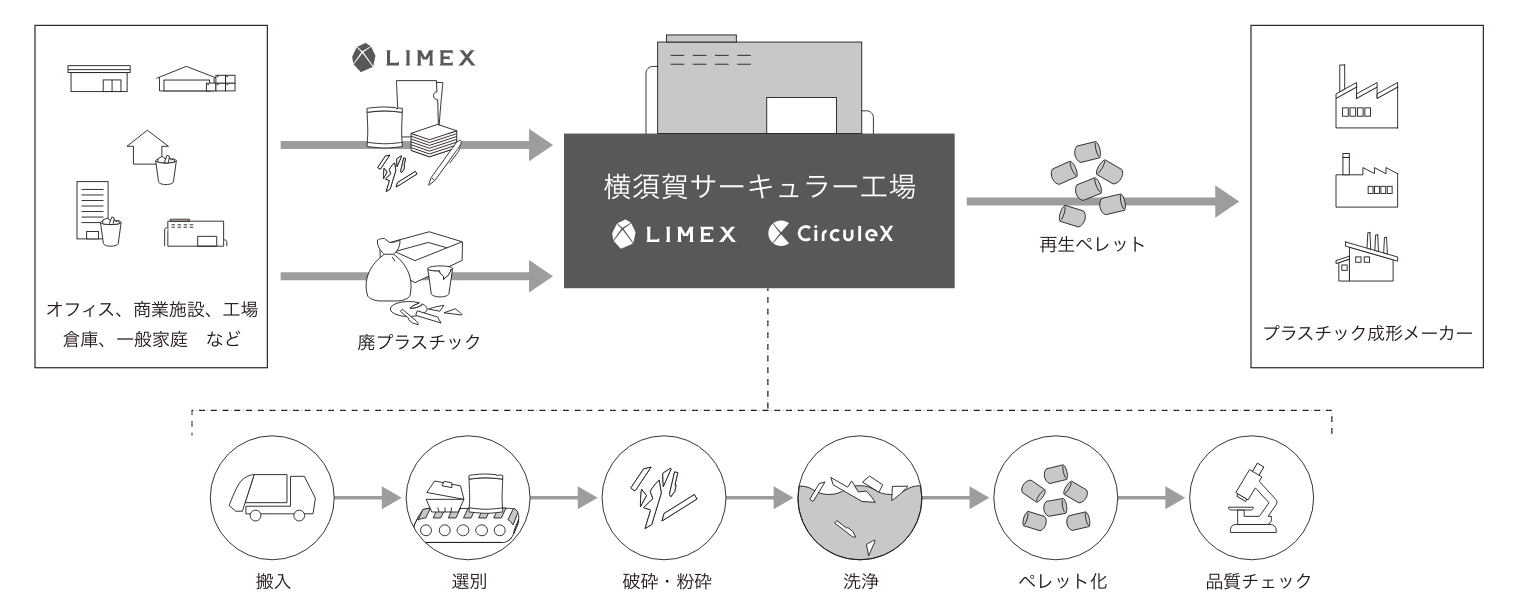

リサイクルプラント運営

近赤外線を用いた最新自動選別技術で、回収した家庭由来の容器包装プラスチック(PCR)を樹脂ごとに自動選別し、高品質な容器包装リサイクル材(容リ材)へマテリアルリサイクルするプラントを2023年より本格稼働しています。動脈産業である素材開発で培った独自の開発技術とR&D機能を活かし、従来の容リ材が抱えていた臭気や物性低下、強度などの課題を解決することが可能に。高品質で価格競争力を持った再生材を安定的に供給します。

横須賀サーキュラー工場の特徴

・汎用プラスチックを樹脂ごとに自動選別し、再生する大規模プラント

海外の大手選別機メーカーと連携し、近赤外線による素材検知・選別(LIMEXのみの自動選別も可)の検証を進め、独自の選別プログラムを開発。

・プラスチックのマテリアルリサイクルプラントとして国内最大級

本工場が備える年間約4万トンの処理能力、年間約2万4000トンの再生ペレットの生産能力は、プラスチックのマテリアルリサイクルのプラントとしては国内最大級の規模。

・横須賀サーキュラー工場では、品質マネジメントシステムの国際規格ISO9001認証を取得しています。 国際基準に準拠した厳格な管理体制のもと、高品質な再生材料を安定的に供給します。

リサイクルプラントの運営拡大戦略

1. 容器包装リサイクル協会ルート

複数の地方行政と容リ協会を介した間接有価引受契約を獲得【令和5年度13,290t 強】

2. 大臣認定ルート(プラ新法)

横須賀市から直接有価引受契約を獲得

詳しくはこちら資源循環プロデュース

資源循環プロデュース事業において当社は、事業所から排出される廃プラスチックや市場に流通する再生可能な資源を有価で買い取り、スクラップ・粉砕品・ペレットなど形状を問わず、高度選別機や材料設計技術、再生原料コンパウンダーとの協働によりその品質を高めたうえで、再生材を必要とする成形メーカー、製品メーカー、ブランドオーナーとのマッチングを行っています。その際、当社が「物性」「プロセス」「トレーサビリティ」を保証した再生材を「プレミアム再生材 品質保証グレード」として販売することで、認定リサイクラーは自社の高い技術力と品質を市場に効果的に訴求することが可能となり、再生材を利用するメーカーは、自社の要望にマッチした高付加価値再生材を安心して選択することが可能となります。

- リサイクルパートナー

- 250社

- 国内プラスチック取扱量

- 35,000トン

GRS認証、RCS認証を取得

特徴

- ・豊富なパートナーとの連携により、回収から一次加工まで一気通貫で対応

- ・リサイクルが難しかった産業廃棄物も資源化

- ・有価物と産廃の一括引受で手続きの効率化

- ・東南アジアなどの海外拠点の資源循環もサポート

- ・処分業許可証:第05822230314号

TBM、品質保証付きプレミアム再生材の販売と認定リサイクラー制度を開始

当社は2025年より、品質保証付きプレミアム再生材の販売と認定リサイクラー制度を開始しました。本取り組みにより、再生材を利用するメーカーは、より高い安心感をもって再生材を選択できるようになる一方、認定リサイクラーは自社の高い技術力と品質を市場に対して効果的に訴求することが可能となります。 プレスリリースを見る >

詳しくはこちら資源循環プラットフォーム (Maar再生材調達)

「Maar 再生材調達」はデジタルプロダクトパスポート(DPP)システムを活用することで、再生材の付加価値を高めるとともに、トレーサビリティを確保した再生材および再生材利用製品の普及・拡大を可能にします。製品・成形メーカー等の「再生材等を利用して製品を製造する企業」と、廃プラスチック排出企業・リサイクラー・コンパウンダー等の「再生材等を販売する企業」が、本サービス上で売買を希望する再生材の要求事項データを登録し、これまでの資源循環の取り組みで培った当社の豊富なノウハウを有するセールス人材が各取引をサポートすることで、精度の高い再生材取引のマッチングを可能とします。

Maar再生材調達の取り組み

「Maar 再生材調達」の利用促進に向けて

商工中金と連携を開始

全国7万5000社超のネットワークを有する商工中金との連携により再生材調達プラットフォーム「Maar」の社会実装を加速させ国内の資源循環市場を活性化させます。トレーサビリティが担保された再生材の流動性を高めることで、中小企業を中心とした日本各地の地域循環を促進し、中小企業のサステナビリティの取り組みを推進します。

横須賀工場から出荷される再生素材のトレーサビリティを確保するための実証実験をJEMS社と実施

横須賀工場において株式会社JEMSのデジタルツールを活用したトレーサビリティ実証を開始し再生素材の出自を詳細に可視化します。製造工程や原料情報の透明性を確保することで調達時の不確実性を排除し品質への信頼に裏打ちされた高付加価値な再生材を提供します。

官民共創型アクセラレーションプログラム「ソーシャルXアクセラレーション」で審査員特別賞を受賞

官民共創型アクセラレーションプログラム「ソーシャルXアクセラレーション」にて審査員特別賞を受賞。再生材や再生原料の調達を支援するプラットフォーム「Maar 再生材調達」を通じて、再生材を活用した地域産業の発展をテーマにした、日本初の「新たな地域インフラ」の提案を行いました。

一般社団法人資源循環推進協議会との連携強化

TBMが事務局を担う一般社団法人

資源循環推進協議会が設立。

大企業やスタートアップ

金融事業者、有識者、地方自治体等

資源循環の各主体者と協働し、

2,400以上の会員が参画。

サーキュラエコノミーの実現に向けた

①「政策提言」

②「社会実証・実装」

③「共有・発信」の活動を推進します。

お問い合わせ

再生材のお見積りや導入に関するご不明点、再生材の売買に関するご相談などがございましたら、

下記よりお気軽にお問い合わせください。