最終更新日: 2025年3月26日

紙代替としてのLIMEX

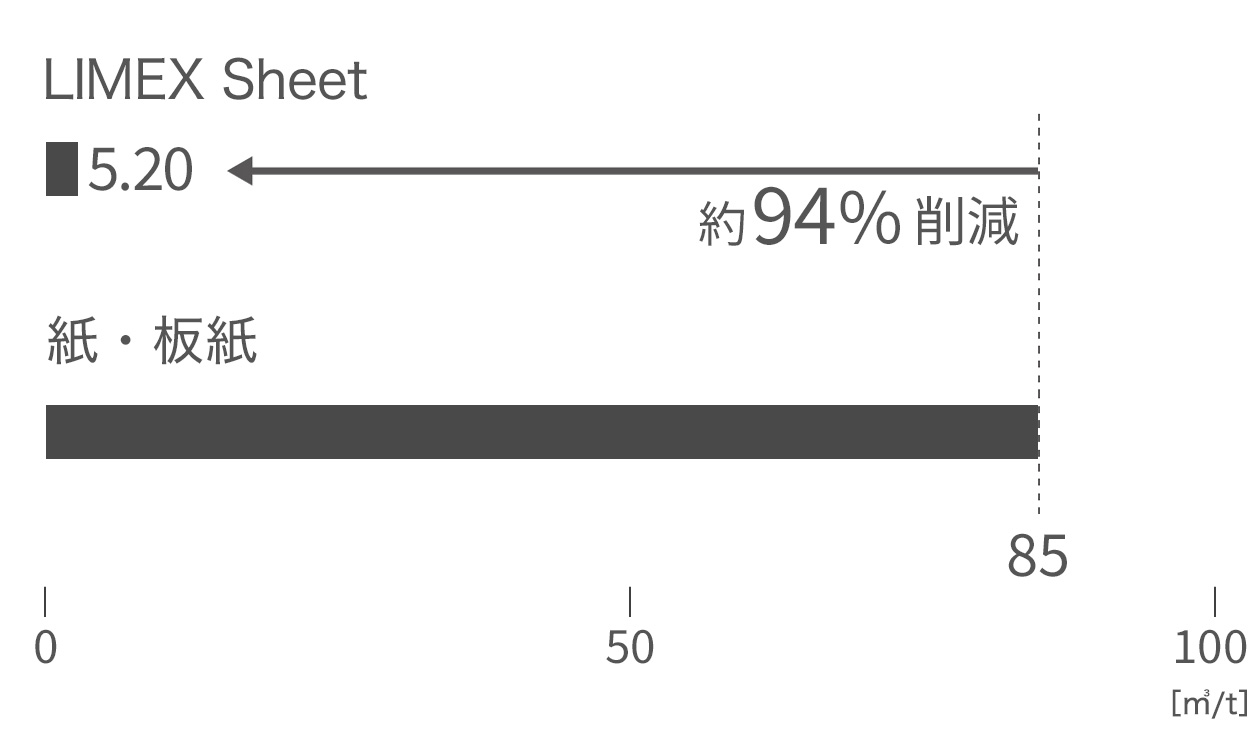

炭酸カルシウム(石灰石)などの無機物を主原料とするLIMEXは、紙の代替として使用することが可能な素材です。LIMEXは、製造時に水をほぼ使う必要がありません。LIMEXは紙と比較し、シート1トンあたりの工場における水利用量を約94%削減することが可能です。パッケージや、名刺、冊子やメニュー表など、様々な用途でご利用いただけます。

LIMEX Sheet製品は、単一素材で設計された製品と同様にリサイクルが容易であり、 事業者・消費者・自治体と連携したマテリアルリサイクルの事例が数多くあります。LIMEX Sheet製品は可燃で焼却処理も可能ですが、廃棄物として処分するのではなく、資源として再生していく取り組みを進めています。

工場における水利用量

(出典)紙・板紙生産トン当たりの新水利用原単位の推移:日本製紙連合会

(出典)東北LIMEX工場での水利用量を生産量で除した値:2025年1月 TBM調べ

※LIMEX Sheet:150μm以上の厚みの品番

紙代替としての特徴

水や森林資源の使用量削減

製造工程で水資源をほとんど使用せず、森林資源を用いないため、枯渇リスクの高い資源の保全に貢献しています。

優れた耐久性と耐水性

紙と比較し耐久性・耐水性に優れているため、ラミネート加工を必要とせず、繰り返し利用するメニュー表やマップ等の利用に適しています。

上質な質感と鮮明な印刷

マットでしっとりした上質な質感が特徴で、色の再現性に優れています。

ストーンペーパーとの違い

LIMEXは、TBMが日本国内で自社開発(特許取得)したプラスチックや紙の代替となる複合素材です。

台湾メーカーが開発したストーンペーパーと呼ばれる石灰石を使った合成紙がありますが、LIMEXはストーンペーパーと基本特許も異なります。

印刷物に使用される押出成形、袋などの包装に使用されるインフレーション成形だけでなく、プラスチック製品を代替する材料として真空成形、射出成形など多様な成形方法に対応できます。

ストーンペーパーは、台湾のメーカーが開発した中間製品の名称であり、LIMEXは素材の名称であるため、製造工程においても名称の位置づけが異なります。

| 素材名 | 中間製品名 | 用途 | 印刷物 (名刺) |

真空成型物 (食品容器) |

射出成型品 (スマホケース) |

インフレーション (レジ袋) |

製造国・石灰石の産出国 |

|---|---|---|---|---|---|---|---|

| LIMEX | LIMEX Pellet | プラスチック代替 | × | 〇 | 〇 | 〇 | 日本・ベトナム |

| LIMEX | LIMEX Sheet | 紙代替 | 〇 | 〇 | 〇 | × | 日本・ベトナム |

| なし | ストーンペーパー | 紙代替 | 〇 | × | × | 〇 | 台湾・中国 |