最終更新日: 2025年11月27日

石灰石について

世界中に豊富に存在する資源

LIMEXの原料である石灰石は、世界中で豊富に存在し、日本でも100%自給自足(*1)できる資源です。豊富な石灰石を用いることで、プラスチックや紙を製造する際に必要とする石油や木材、水など偏在性が高く枯渇リスクも高いとされる資源の利用を抑え、地球規模で資源保全に貢献できます。

世界の人口はこれからも増え続け、プラスチックや紙の需要はますます増加します。その点、石灰石はその豊富さ故、プラスチックや紙を代替する原料としては供給の安定性に優れており、価格も安価です。そのため石灰石から作れるLIMEX には、水資源が乏しく紙を輸入に頼っている国々や、人口増によって資源消費が加速度的に進むアフリカ地域など、世界中から熱い視線が注がれています。単なる新素材にとどまらず、世界中に新たな富を分配する事業でもあるのです。

また、石灰石の主成分は炭酸カルシウムです。世界各国でいま、CO₂を回収・固定化して有効利用するCCU(Carbon Capture and Utilisation:二酸化炭素の回収・有効利用)の技術開発が進められています。その一環でTBMは社外のパートナーと連携し、CO₂を固定化して炭酸カルシウムを生成することに取り組んでいます。将来的には鉱物資源である石灰石でなく、工場や発電所などから排出されたCO₂を原料とした炭酸カルシウムによって、温暖効果ガス排出量のさらなる削減とともに、カーボンネガティブを実現する素材を目指しています。

国内で自給自足できている石灰石の国内生産量と出荷量

出典:石灰石鉱業協会

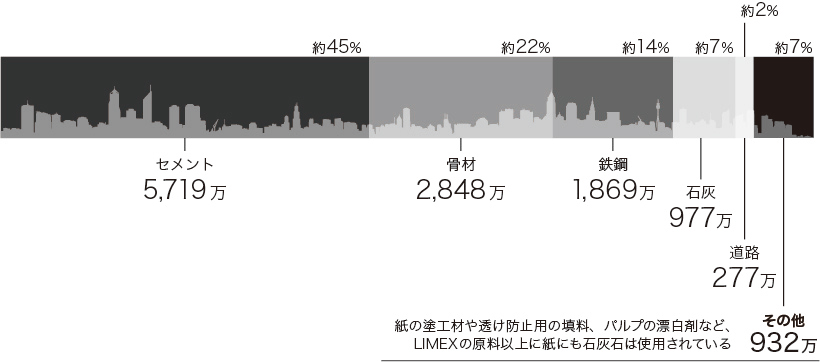

日本における石灰石の用途はグラフの通り、その多くがまちづくりに使われています。馴染み深く、われわれの暮らしになくてはならない資源といえます。当社の自社工場で生産されているLIMEXで使用される石灰石の量は、国内使用量の0.01%にすぎません。

ちなみに、紙の塗工剤や填料(透け防止)として年間約60~90万トン、他にもパルプの漂白剤原料としても石灰石が使用されています。

石灰石の大半はまちづくりに使われる 石灰石の用途別構成比

合計:12,623万t(輸出量を除く)

出典:石灰石鉱業協会

LIMEXが使用している石灰石

LIMEXに使用する石灰石は、TBMが直接石灰鉱山から採掘しているわけではなく、従来のセメントや鉄鋼製造向けに供給しているサプライヤーから炭酸カルシウムパウダーのかたちで調達しています。

石灰石採掘による環境や社会への影響はゼロではありませんが、抽出・精製工程で多量のエネルギーや環境負荷が高い物質を要する鉱物も多く存在する一方、石灰石はそうした工程を必要としません。他の鉱物で懸念されるような環境影響や社会的なリスクは極めて小さいと考えています。

また、TBMでは各サプライヤーの環境・社会配慮状況の把握に努め、高度な管理を促しています。サプライヤーは、環境マネジメントシステムを有するなど、当社の環境・社会配慮の方針についても協力いただいています。

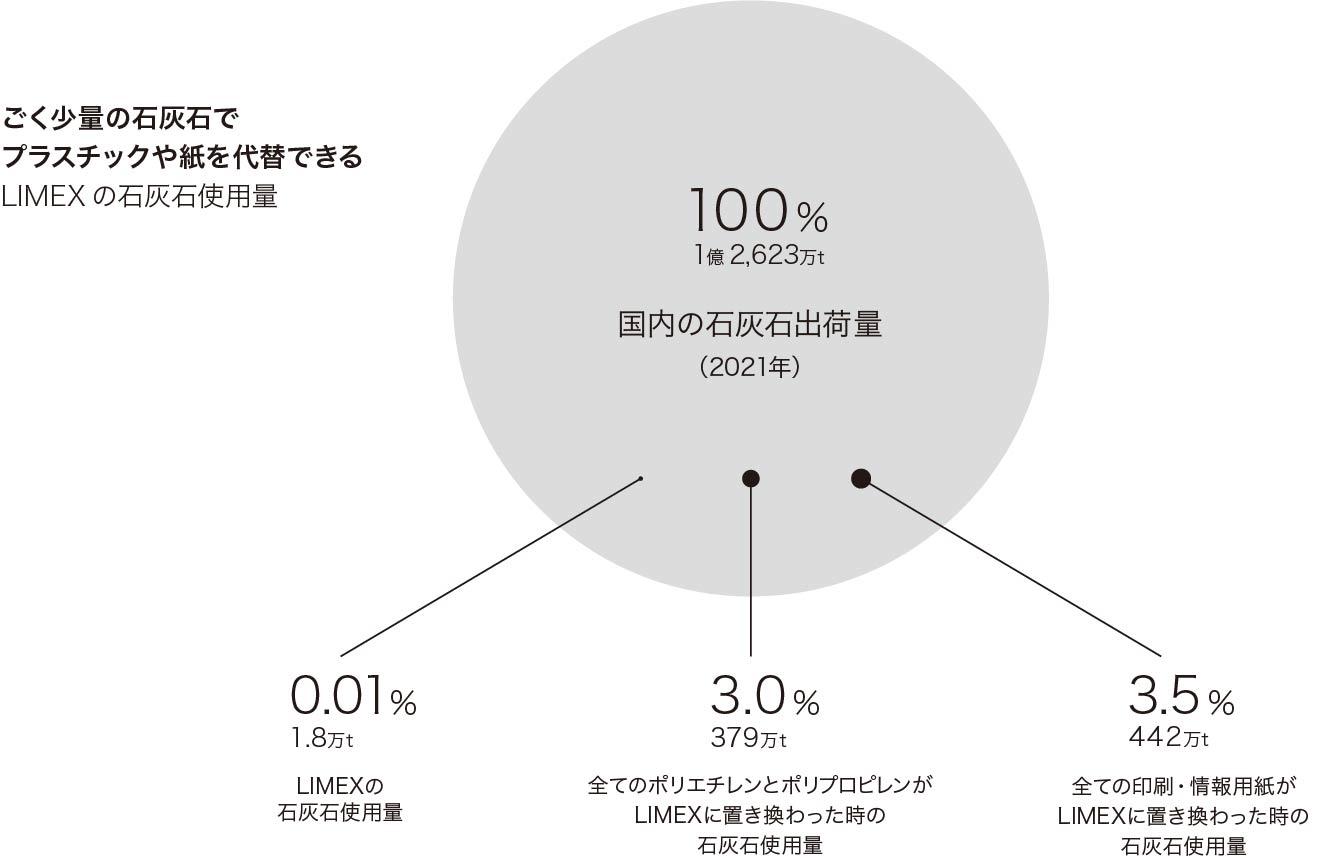

LIMEXはどのくらい石灰石を使っているのか

前述の通り、当社保有の自社工場で生産されているLIMEXに使用する石灰石の量は、国内石灰石出荷量の0.01%です。

また、石灰石は、紙の塗工剤や填料(透け防止)として年間約60~90万トンとLIMEXの30〜50倍の量が使用されており、他にもパルプの漂白剤原料としても使用されています。

今後、LIMEXがさらに普及するに連れ石灰石の使用量は増えることが見込まれますが、仮に日本で生産される印刷・情報用紙年間約631万トン(*1)すべてをLIMEX Sheetで置き換えた場合でも、必要な石灰石は約379万トン。

石灰石総出荷量に対してわずか3.0%程度です。同じく仮に国内のプラスチック生産量全体の約46%を占めるポリエチレンとポリプロピレン(450万トン.〈2019年〉*2)をすべてLIMEX Pelletで置き換えたとしても、

必要な石灰石は約442万トン(*3)となり、日本国内における石灰石総出荷量に対して約3.5%程度です。

現在はわずか0.01% LIMEXの石灰石使用量

石灰石とCO₂排出

昨今、あらゆる製品・サービスがそのライフサイクルにおいて、どんな環境負荷を及ぼしているかを定量的に把握し、低減に取り組むことが求められています。

その中でも温室効果ガス、とりわけCO₂の排出に最も注目が集まっています。

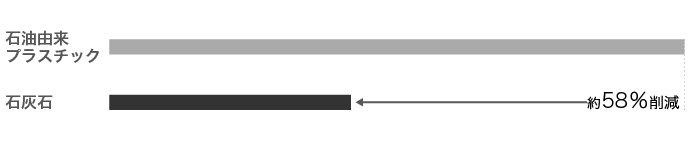

石油由来プラスチックは、原油を掘削して製油所に運搬した後、ナフサを分留し、取り出したモノマーを重合・ポリマー化して製造されます。

その加熱工程等を通じて多くのエネルギーが消費され、CO₂を排出します。

一方、石灰石は、採掘した石灰岩を粉砕するというシンプルな製造・加工工程のため、原料調達段階で必要とされるエネルギーは石油由来プラスチックと比較して少量で済みます。

もちろん、石灰石も焼却すればCO₂を排出します。

しかし、ポリプロピレンなどの石油由来プラスチックと比較すると、分子構造の違いにより燃焼時のCO₂排出量は約58%少なくなります。

石灰石を原料としたLIMEXの、ライフサイクル全体(原料調達段階から処分)を通じたCO₂等の温室効果ガス(GHG)排出量のデータについて、詳しくは以下をご覧ください。

LIMEX Pellet LCA

LIMEX Sheet LCA

燃焼時のCO₂排出量

(出典)PP・PEの燃焼時のCO₂排出量: 一般社団法人プラスチック循環利用協会,

(出典)LCIデータべース IDEA version 2.3, 国立研究開発法人産業技術総合研究所安全科学研究部門 社会とLCAグループ, 一般社団法人サステナブル経営推進機構より試算