最終更新日: 2025年5月2日

LIMEX(ライメックス)は、TBMが日本で独自に開発したプラスチックや紙の代替となる、炭酸カルシウムなどの無機物を50%以上含む、無機フィラー分散系の複合素材です。 資源枯渇や気候変動に貢献できる環境配慮型素材のLIMEXは、国内の自社工場や国内外のパートナーと連携してファブレスモデルによる素材のOEM生産が可能です。従来の製品と比較して、石油由来のプラスチックの使用量や製品のライフサイクルで生じるCO₂の排出量の削減が可能です。袋や容器包装、印刷物、販促物等の製品用途で既に10,000以上の企業や自治体に採用されています。

石灰石について

LIMEXという素材名は、石灰石の英語名「Limestone」と、「無限の可能性」を意味する「X」を掛け合わせたものです。石灰石は、炭酸カルシウム(CaCO3)を主成分とし、世界中に豊富に存在する岩石です。日本国内にも220の石灰石鉱山が稼動し*1、資源に乏しい日本でも自給自足できる数少ない資源です。そのため、価格が安価かつ安定しています。

LIMEXなら、水資源の乏しい地域や内陸部でもその国で採れる原料を使って生産できます。立地による制約を受けにくく、長距離輸送を必要としないコンパクトなサプライチェーンで地産地消のモデルを、世界中で構築できます。

LIMEXの世界特許

2014年に「LIMEX」の国内特許を取得。今では、世界40ヵ国以上で200件以上のLIMEXに関する特許を権利化しています。 知的財産を活用した取り組みが評価され、経済産業省 特許庁が表彰する令和4年度「知財功労賞」において、知財活用ベンチャーとして「経済産業大臣表彰」を受賞いたしました。 また、COPやG20の国際会議で紹介される他、日本の優れた技術としてUNIDO(国際連合工業開発機関)のサステナブル技術普及プラットフォームに登録されています。 今後、日本発の技術として、技術およびブランド輸出を行い、世界で当たり前に使われる素材を目指します。

LIMEXの製造方法

LIMEXの原料構成は、50%以上(重量比)が炭酸カルシウムなどの無機物で、残りは熱可塑性樹脂と各種添加剤です。これらを均一に混練し、溶融状態の複合体(コンポジット)にすることに独自の技術があります。

溶融状態のコンポジットを押出機から均一な大きさ・形状にカットし、ペレット(粒状)にした中間製品がLIMEX Pellet(ライメックス ペレット)。

一方、Tダイと呼ばれる金型から押し出されたコンポジットを金属のロールに通し、均一なシート状に成形した中間製品がLIMEX Sheet(ライメックスシート)です。

LIMEXの

多様な成形方法

LIMEXは押出成形、インフレーション成形のみならず、真空成形、射出成形が可能です。複合素材であるLIMEXは、その製造に専用の設備を必要とせず、既存の機械や製造方法を活用してLIMEX製品を成形可能です。 LIMEXは、10,000以上*の企業や自治体等で採用されています。

マテリアルリサイクルを

推進するLIMEX

LIMEXは、石油由来のプラスチックであるポリプロピレン(PP)と比較して、リサイクル前後で流動性や耐衝撃性など樹脂の特性変化が少ないため、物性低下を抑制できるのが特長です。

そのためマテリアルリサイクルに適しており、これまでにも多くのリサイクルの事例があります。

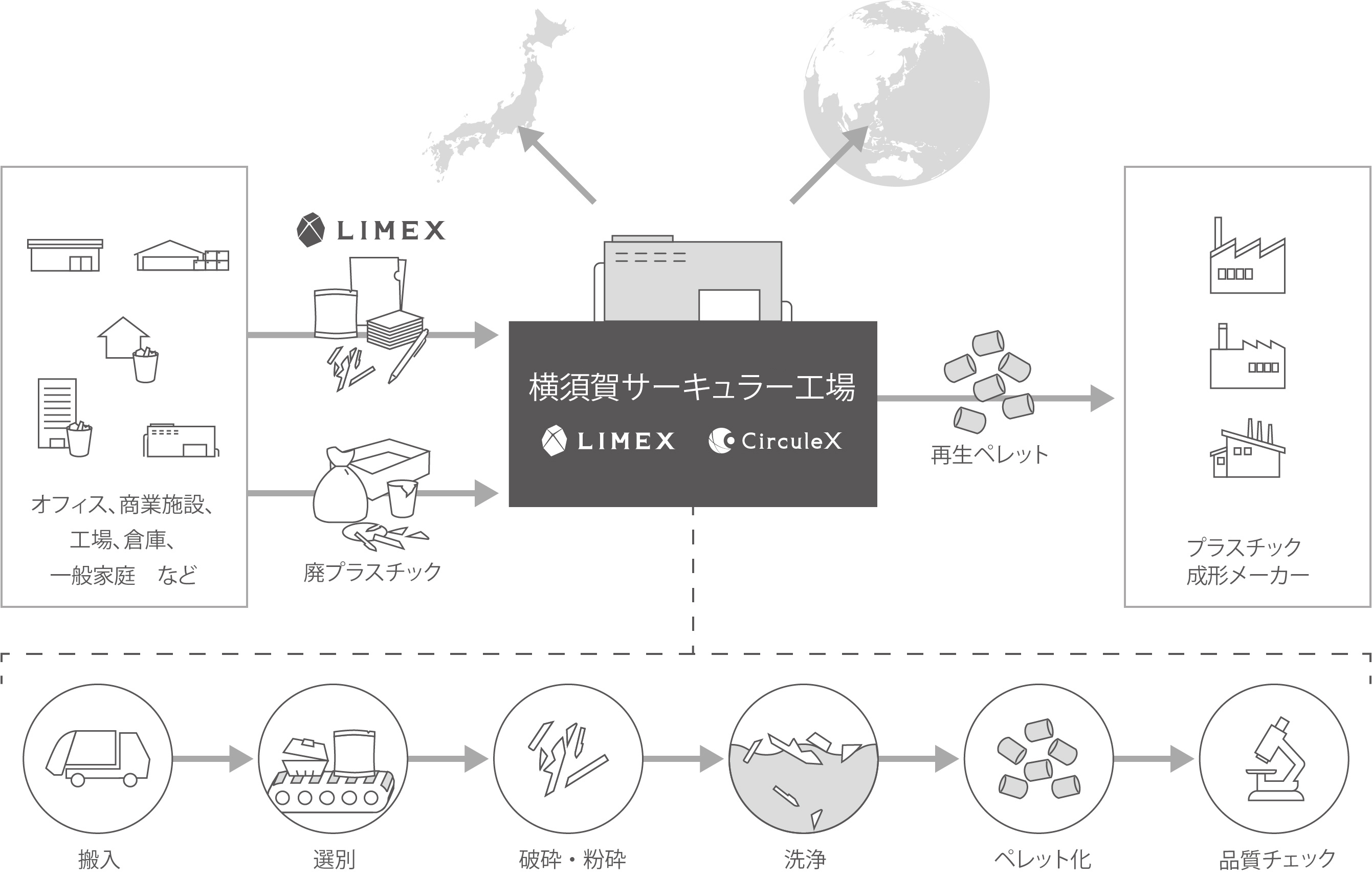

さらに、TBMが運営する国内最大級のリサイクルプラント「横須賀サーキュラー工場」では、使用済LIMEXと併せて廃プラスチックも回収し、自動選別・再資源化することができます。

この「横須賀サーキュラー工場」をモデルケースとして、廃プラスチックの処理を焼却・熱回収に頼る国内各エリアや、家庭におけるプラスチック分別の仕組みが未発達な海外エリアに対しても、リサイクルシステム構築の解決策として本スキームを展開していく計画です。

TBMは世界全体で高まるプラスチック代替素材や再生材料へのニーズに応えるべく、使用済みのLIMEXや使用済みのプラスチックを原料として再生利用したCirculeXや、使用済みLIMEX製品やプラスチック製品の資源循環をコーディネートするサービスMaaRを通じて、マテリアルリサイクルを推進し、サーキュラー・エコノミーの実現に貢献しています。

資源循環について詳しくはこちらへ

LIMEXの明日

LIMEXの資源循環に関しては、TBMが運営するリサイクルプラント「横須賀サーキュラー工場」や既存のリサイクル設備を活用した資源循環を推進しています。さらに、横須賀サーキュラー工場をモデルに、LIMEX及び従来燃やされていたプラスチックのマテリアルリサイクルを国内外で展開していく予定です。そのために、事業者・一般消費者からのLIMEX、プラスチックを回収・再資源化する資源循環のインフラ形成にも注力しています。

技術開発については今、世界中のベンチャー、大企業が、CO₂を資源として捉え、これを分離・回収して有効利用するCCU(Carbon Capture and Utilisation:二酸化炭素の回収・有効利用)に乗り出しています。

その一環でTBMでも社外のパートナーと連携し、工場や発電所などから排出されたCO₂を固定化して炭酸カルシウムを生成することに取り組んでいます。

将来的には鉱物資源である石灰石でなく、排出されたCO₂由来の炭酸カルシウムを主原料としたLIMEXによって、温暖効果ガス排出量のさらなる削減を実現する素材を目指しています。

また、一方、LIMEXの副原料であるプラスチックについては、すでに植物由来や生分解性、海洋生分解性を備えたプラスチックやリサイクルプラスチックに置き換える技術開発を進め、実際の製品化も始まっていますが、その量産化も含めて一層の利用拡大を図っていきます。

現在のLIMEXの環境性能をさらに高めるために、LIMEXの主原料である「炭酸カルシウム」と副原料である「プラスチック」の材料適合性を広げ、CO₂などGHG排出の削減貢献量を増大し、将来的にカーボンネガティブの素材開発を実現してまいります。

CO₂を再利用した次世代LIMEXについて詳しくはこちらへ

LIMEXとSDGs

SDGsは、2015年9月の国連サミットで採択された「持続可能な開発のための2030アジェンダ」にて記載された2016年から2030年までの国際目標です。

TBMは、バリューチェーン上の各ステージとSDGsの169のターゲットとの関連性をマッピングし、事業とSDGsとの接点を特定しました。

その際、TBMのバリューチェーンがSDGsに与える影響と、SDGsを取り巻くトレンドがTBMのバリューチェーンに与える影響との両面から分析を行いました。

そして、TBMの事業が特に大きなインパクトをもたらしうる8つの目標を、中核目標として定めました。

<中核目標>

LIMEX事業は、SDG12「責任ある消費と生産」を中心として、6「水資源の保全」、13「気候変動対策」、14「海洋生態系の保全」、15「陸域生態系の保全」、8「雇用の創出」、9「産業の創出」、17「協働」の8つの目標を中核目標とし、積極的に貢献します。

LIMEXを対象とする

JSA規格発行

LIMEXを含む「無機物を主成分とする無機・有機複合マテリアル」の定義を明確化し、市場拡大及び品質安定化を進め、公正な取引につなげることを目的としたJSA規格(JSA-S1008)が、2021年4月19日に一般財団法人日本規格協会より発行されました。

JSA-S1008では、日本国内における「容器包装リサイクル法」の特定事業者の再商品化(リサイクル)義務の対象外とされている、主要な構成素材(構成する素材のうち、質量分率が最大の素材)が一種類の無機物であり、無機物の総量が質量分率で50%を超える材料について、「無機物の総量に関する質量分率の測定」、「熱可塑性樹脂の有無の確認」及び「主要な構成素材及び第二素材の種類及び質量分率」の確認・試験方法などについて規定しています。