Developer story

Tomoya NakamuraNext Generation Business Promotion Office Manager/Administration Headquarters Assistant Manager

After joining Accenture's Strategy Group in 2008, he has experience in a wide range of projects including medium-term planning for manufacturing clients, new market entry strategy formulation, sales reform, and digital transformation. In 2017, he joined TBM Co., Ltd. and was involved in overseas expansion and application development. In 2018, he was involved in the grouping of Bioworks Co., Ltd. and became a director. In 2021, he was involved in a capital and business alliance with the SK Group and became a director of SK TBMGEOSTONE, a joint venture with the SK Group.

Challenges to popularize CCU technology

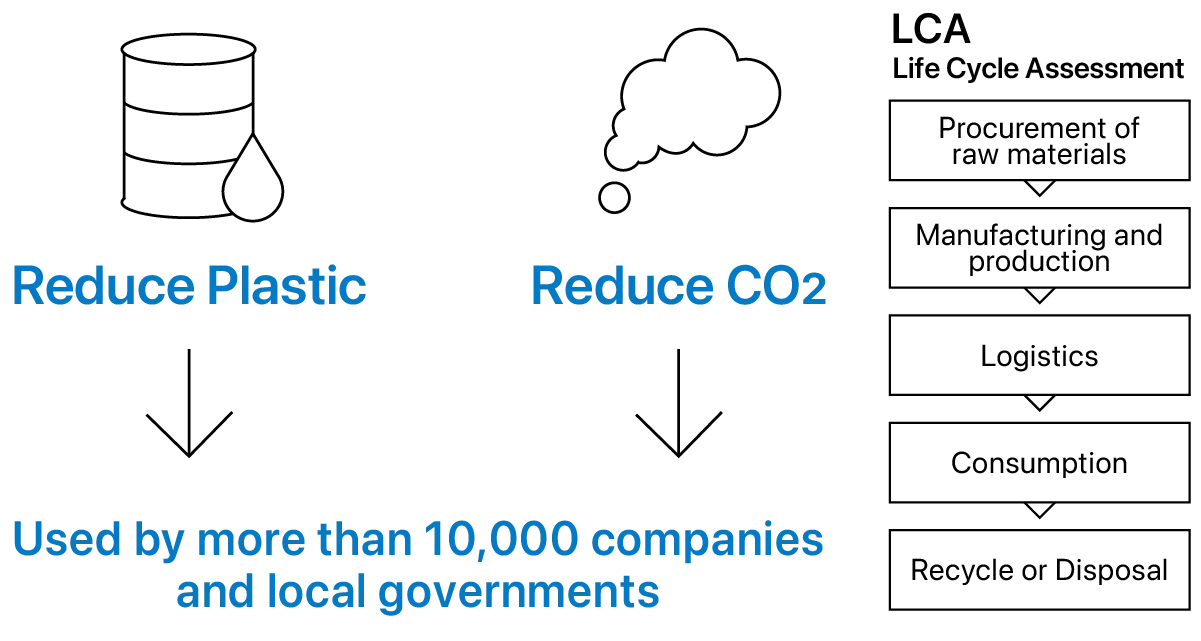

We are very happy to announce that we have set our sights on developing next-generation LIMEX, which captures CO 2 from exhaust gas and uses it as a raw material.

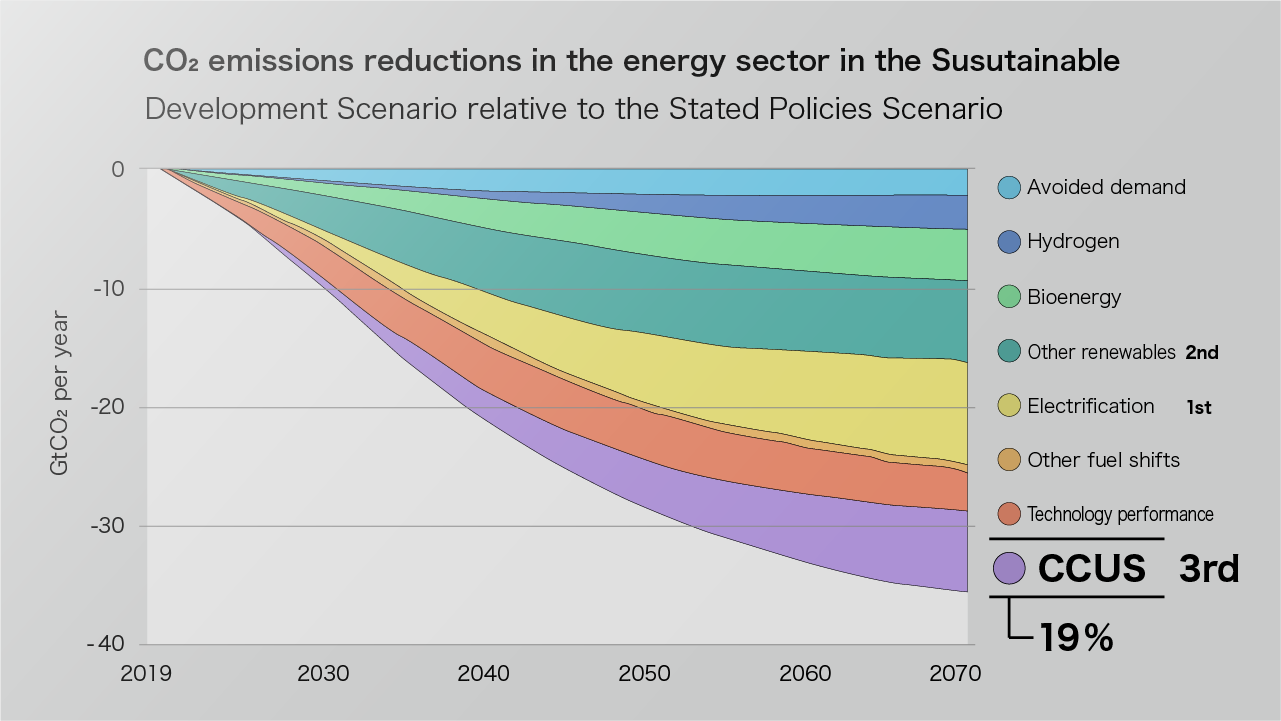

In order to balance population growth, economic development in developing countries, and decarbonization, it is essential not only to reduce CO 2 emissions, but also to absorb and reuse emitted CO 2. So, for the energy sector to achieve carbon neutrality in 2070, CCUS will have to account for approximately 19%.

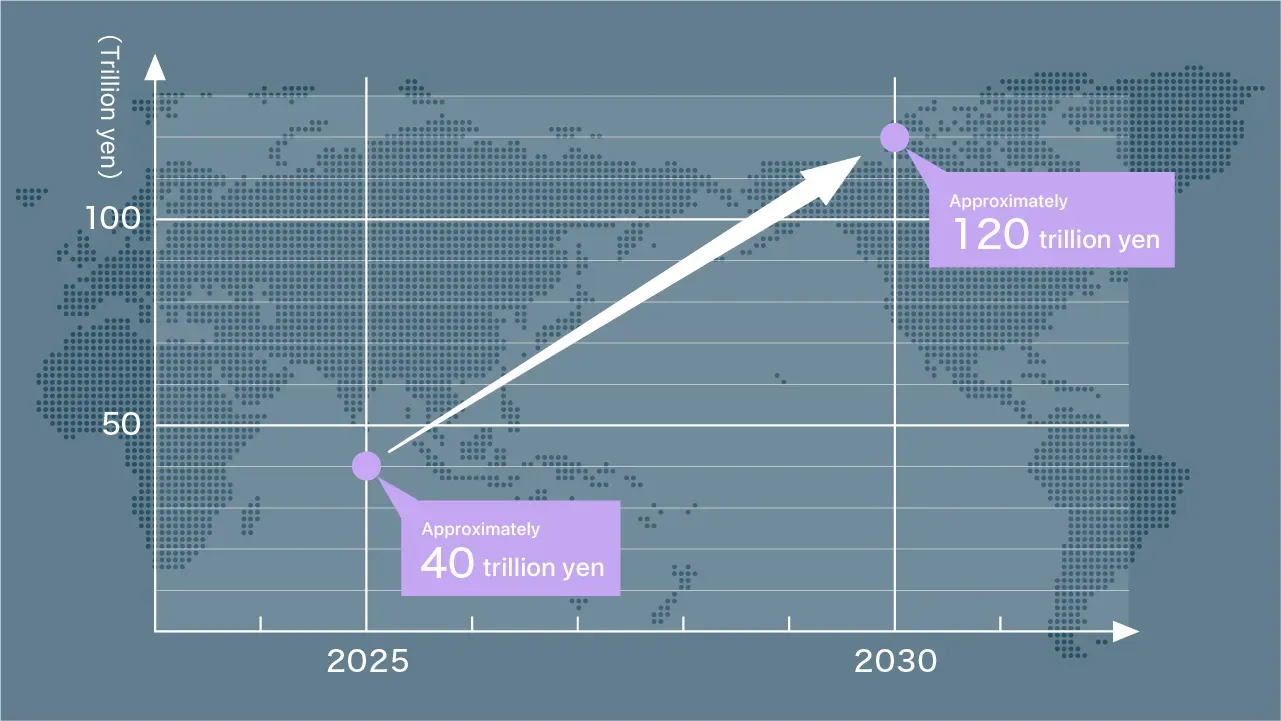

However, we cannot wait until 2070. According to the Ministry of Economy, Trade and Industry's carbon recycling roadmap, products using CCU technology will not be widely available until around 2030, but we are working to bring this forward and spread products using CCU technology into society as soon as possible. I have tried my best.

Due to technical and quality issues, carbonates containing calcium carbonate, which are made from CO 2, were considered to be mainly used as raw materials for concrete and cement, but the cost was not suitable. Next-generation LIMEX is a high-value-added outlet for this calcium carbonate, and as a company aiming to become a top player in the sustainability field, we feel that we have a responsibility to take the lead in spreading CCU technology through next-generation LIMEX. .

In Japan's basic policy for achieving GX, the content of public comments from TBM has been recognized, and measures to support the introduction and demand stimulation of calcium carbonate products should be added to the section on CO2 reduction concrete, etc. It's done.

Although our challenge has only just begun, we will continue to strive to popularize CCU technology and meet the expectations of the countries, local governments, and many companies that support us. Thank you for your continued support. .

Yorinobu Takamatsu Technology Center Director

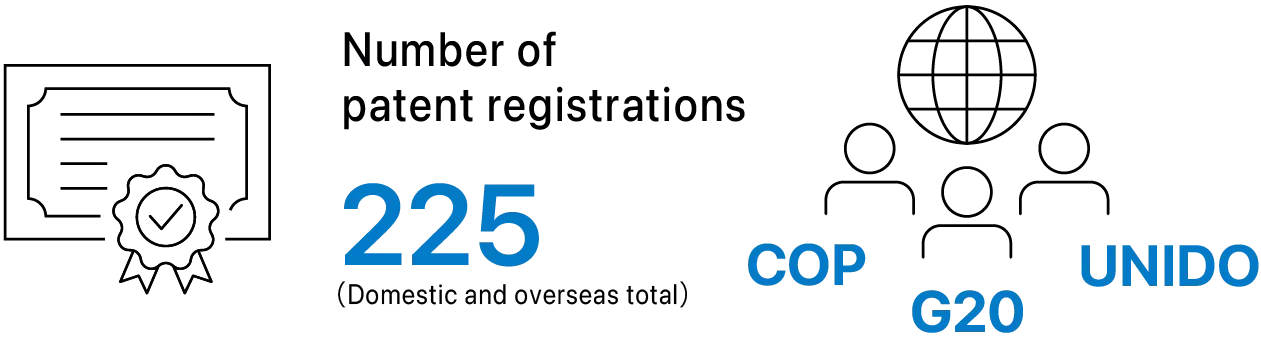

After graduating from Waseda Graduate School, he engaged in research and development of polymer technology at 3M Japan Co., Ltd. and held the position of Senior Specialist (Technical Ladder). Engaged in research and development of molecular design and polymerization technology for adhesives and adhesives, mainly based on acrylic polymers, and application to manufacturing technology. He has filed 108 patent applications in Japan (54 international applications), obtained 43 patents, launched various products, and contributed to annual sales of approximately 20 billion yen. Joined TBM in 2021. At the Technology Center, which is the core of TBM's technology, he is involved in all material development work, including developing compound materials suitable for various uses for LIMEX and CircleX, adding functionality, and developing new products.

Development of next-generation LIMEX that brings together technical know-how

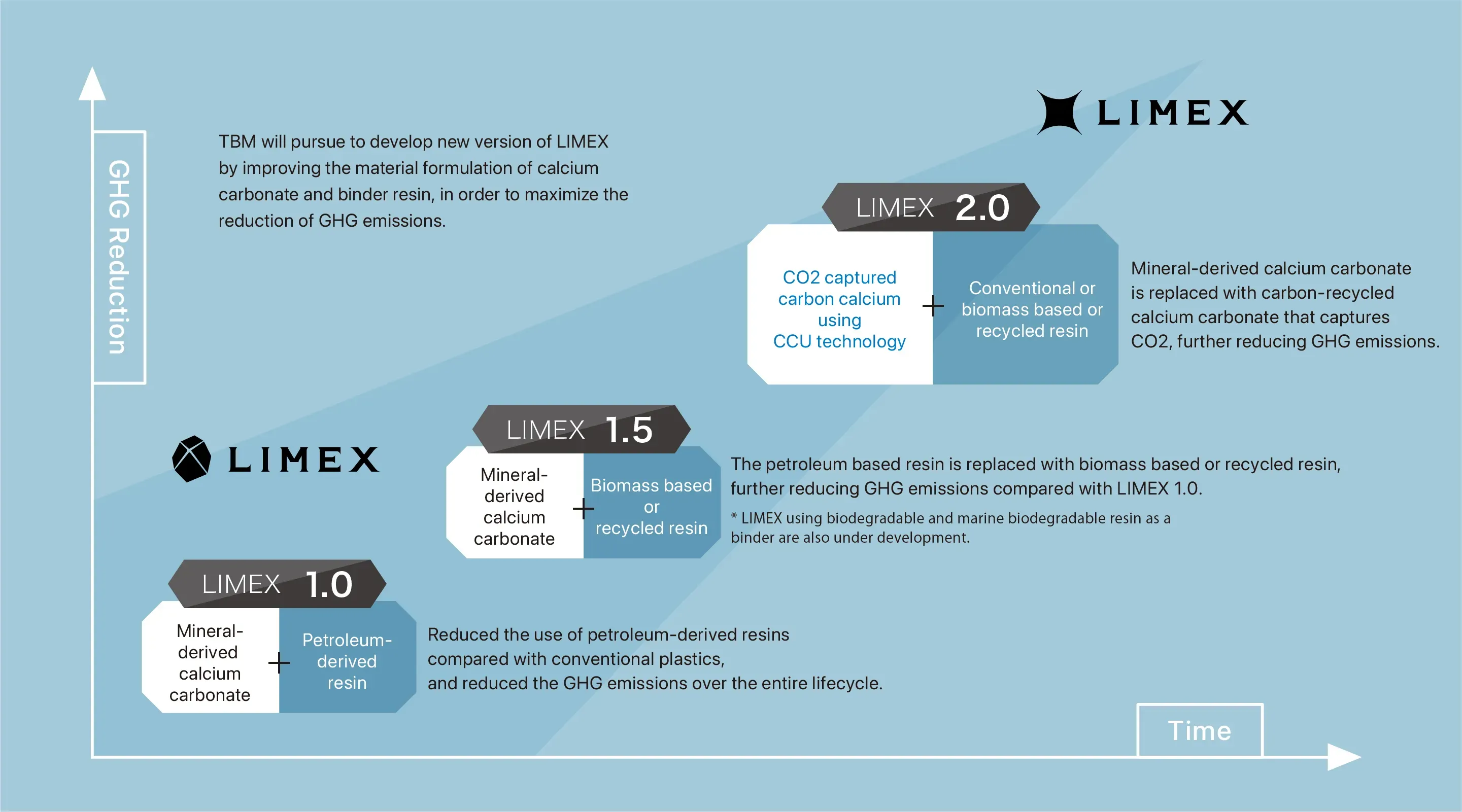

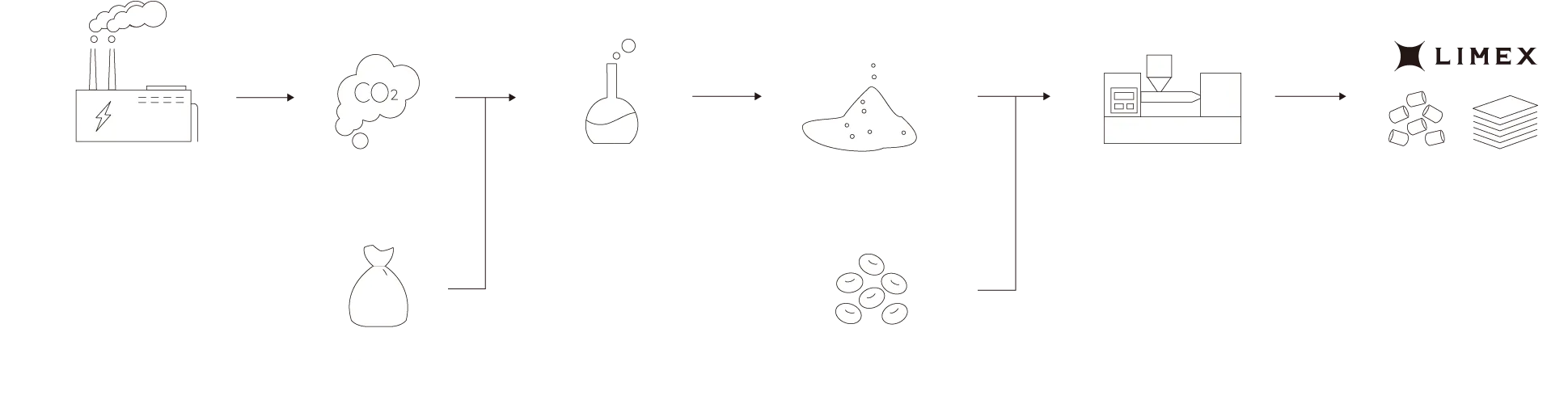

As the director of the Technology Center, our technology base, I am promoting the development of LIMEX for a variety of applications. The core technology of TBM is a kneading technology to uniformly fill the resin with 50% or more of inorganic filler, such as calcium carbonate, and a kneading technology that is compatible with existing molding methods (injection, extrusion, blowing, inflation, vacuum, etc.). This is the compounding technology and molding technology.

Calcium carbonate obtained by CCU technology and the heavy calcium carbonate currently mainly used are similar and different, and we have developed an understanding of their production mechanism, clarified the differences in their properties, and the technical know-how we have accumulated to date. We are bringing together the following and developing it into the next generation of LIMEX. I want to spread LIMEX so that everything around us becomes LIMEX.

Kenshi TakahashiNext Generation Business Promotion Office/Production Technology Department

After completing his studies at Tohoku University Graduate School of Environmental Science, he joined Mitsubishi Materials Corporation. In addition to engaging in the development of waste recycling processes, he also gained experience in supporting the startup of a new factory. In 2021, joined TBM Co., Ltd. Involved in the startup of the Tagajo factory and production process improvements, as well as promoting technological development towards the realization of next-generation LIMEX.

Toward realizing the potential of next-generation LIMEX

Since my university days, I have consistently worked to solve environmental and recycling issues. As I was looking for a new challenge as I turned 30, I came across LIMEX and joined TBM because I was attracted to its innovative concept and its potential to further improve environmental performance through the use of carbon recycling technology. Did.

Technology development for next-generation LIMEX started around April 2021. However, at that time, the in-house research environment was not fully developed, and we had to think about how to specifically conduct research and how to proceed efficiently with limited resources. Meanwhile, with the cooperation of professors at Tohoku University, with whom we had contact, we gradually verified the technology and developed into joint research with the same university. Furthermore, it was selected as a NEDO grant project, accelerating development. Despite all the hardships we faced, I believe we were able to achieve commercialization in a short period of time.

On the other hand, there are still challenges for social implementation. In addition, calcium carbonate produced through carbon recycling has the potential to not only improve environmental performance but also have various functions. We will continue to work hard to realize this great potential.

*1 A state in which the amount of greenhouse gases removed and absorbed is greater than the greenhouse gas emissions from economic activities.

*1 A state in which the amount of greenhouse gases removed and absorbed is greater than the greenhouse gas emissions from economic activities. Source: IEA “Energy Technology Perspectives 2020”

Source: IEA “Energy Technology Perspectives 2020”

Source: The Innovation for Cool Earth Forum (ICEF); Carbon Dioxide Utilizaiton (CO2U) – ICEF ROADMAP 1.0, assuming 1 dollar = 140 yen

Source: The Innovation for Cool Earth Forum (ICEF); Carbon Dioxide Utilizaiton (CO2U) – ICEF ROADMAP 1.0, assuming 1 dollar = 140 yen