最終更新日: 2025年11月26日

LIMEX Pellet

炭酸カルシウム(石灰石)などを主原料とするLIMEX Pellet(ライメックスペレット)は、プラスチックの代替として使用できる素材です。炭酸カルシウム粉末とポリオレフィン系の熱可塑性樹脂、各種添加剤を加熱・混練し、均一に分散させた複合材を、均一な大きさ・形状にカットすることで製造されます。一般的なプラスチックペレットと同様に、さまざまな成形方法に対応でき、既存設備で活用いただけます。

石油由来プラスチックの代替として

「LIMEX Pellet」は、従来の石油由来プラスチックに比べ、石油の使用量を大幅に削減でき、限りある石油資源の保全に貢献できます。また、原材料の調達から処分までのライフサイクル全体でCO₂排出抑制が可能です。主原料の石灰石は石油由来プラスチックと比較し、供給安定性が優れており、価格の変動が少ないため、安定した価格での提供が可能です。

「LIMEX Pellet」は、単一素材と同様に既存のリサイクル設備で容易にマテリアルリサイクルが可能なため、「LIMEX Sheet」を製造する過程で生じる端材を再ペレット化した「LIMEX R Pellet」や、使用済みのLIMEX製品を再ペレット化した「LIMEX UP Pellet」を提供しています。

また、袋製品については石油由来プラスチックを植物由来プラスチックに置き換えた「Bio LIMEX」の素材開発を実現しています。製品のライフサイクルで生じる環境影響については、LCA(ライフサイクルアセスメント)を通して環境影響の可視化とその抑制に取り組んでいます。

ここでは、各種石油由来プラスチックと比較した環境性能について、製品のライフサイクル全体(原料調達段階から処分)を通じてのCO₂等の温室効果ガス(GHG)排出量や石油由来プラスチックの使用量といった詳細データによって具体的にお示しします。

• インベントリデータベース(排出原単位の主な参照先):LCIデータベース IDEA version 2.2(2018/01/18) ・IDEA version 2.3 (2019/12/27)・version 3.2.0 (2022/04/15)|国⽴研究開発法⼈産業技術総合研究所安全科学研究部⾨IDEAラボ|⼀般社団法⼈サステナブル経営推進機構(SuMPO)

• 影響評価⼿法:Climate change IPCC 2013 GWP 100a

他社製品との比較はできません。|特定の製造条件を満たして製造された場合の計算値であり保証値ではありません。|プラスチック削減量の値には製造時のロスは含みません。

LIMEX Pelletを使用したプラスチック代替品としての環境性能

LIMEX Pellet で成形した製品別の、ライフサイクル(原料調達段階から処分)を通じたGHG排出量と石油由来プラスチックの削減量について、既存のプラスチック製品と比較しました。また、袋などインフレーション成形品では、バイオマスプラスチックを活用したBio LIMEXの事例も加えました。

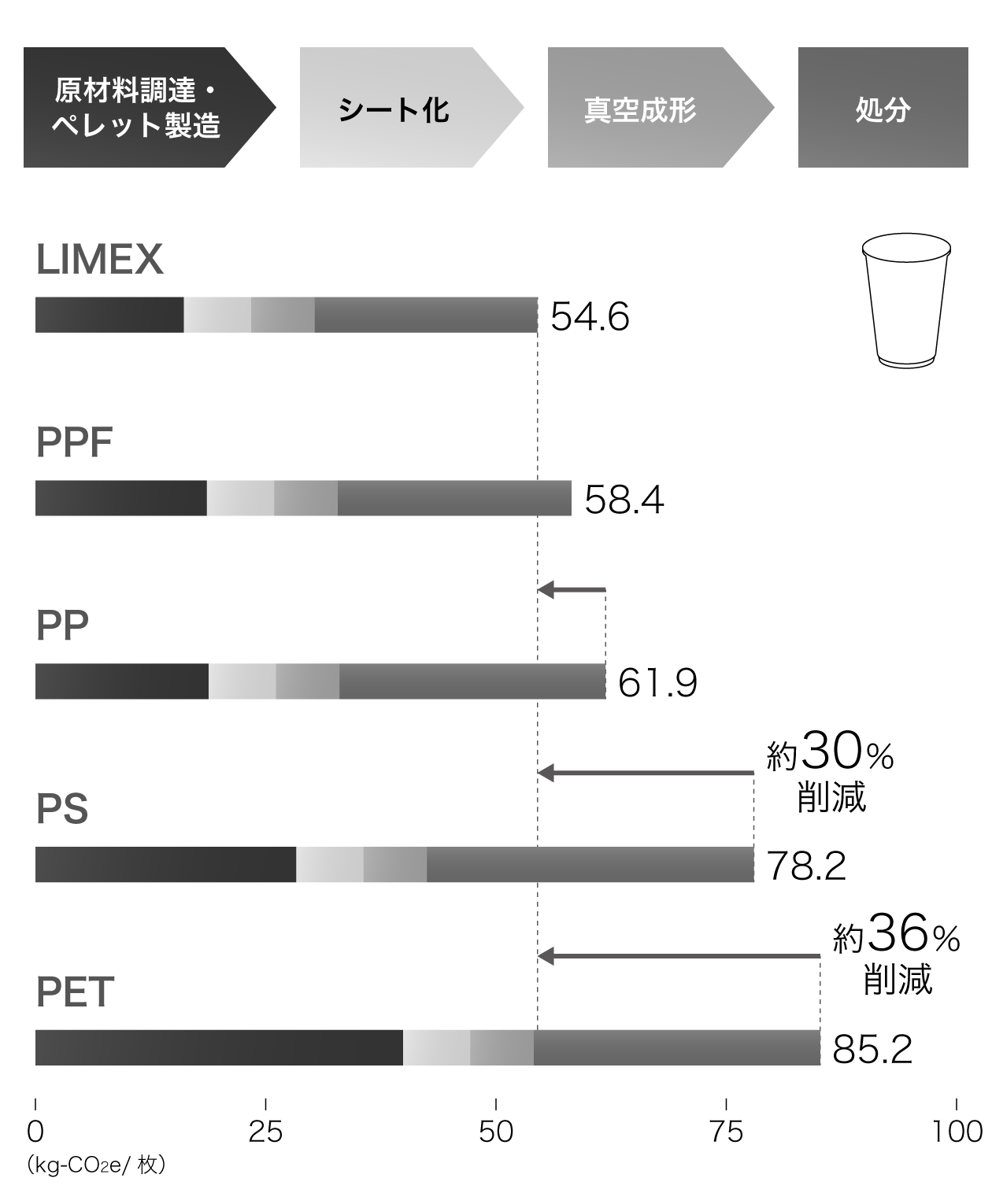

真空成形品

GHG排出量

• 機能単位:飲料カップ1個(LIMEX製で14.4g)

• スコープ:[原材料調達・ペレット製造]〜[シート化]〜[真空成形]〜[処分]

• 成形:成形時の負荷はPPFと同等と想定

• 処分:⼀般廃棄物として焼却されることを想定

• 算定年:2022年

石油由来プラスチック削減量

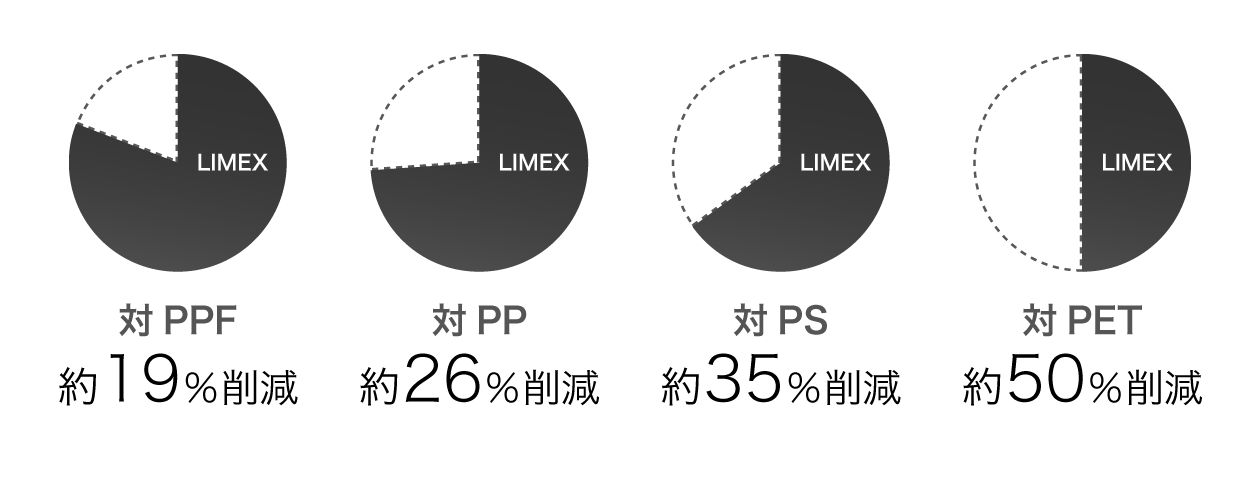

インフレーション成形品

GHG排出量

• 機能単位:レジ袋1枚(LIMEX製で5.8g)

• スコープ:[原材料調達・ペレット製造]〜[成形]〜[輸送]〜[処分]

• 処分:⼀般廃棄物として焼却されることを想定

• 算定年:2019年

石油由来プラスチック削減量

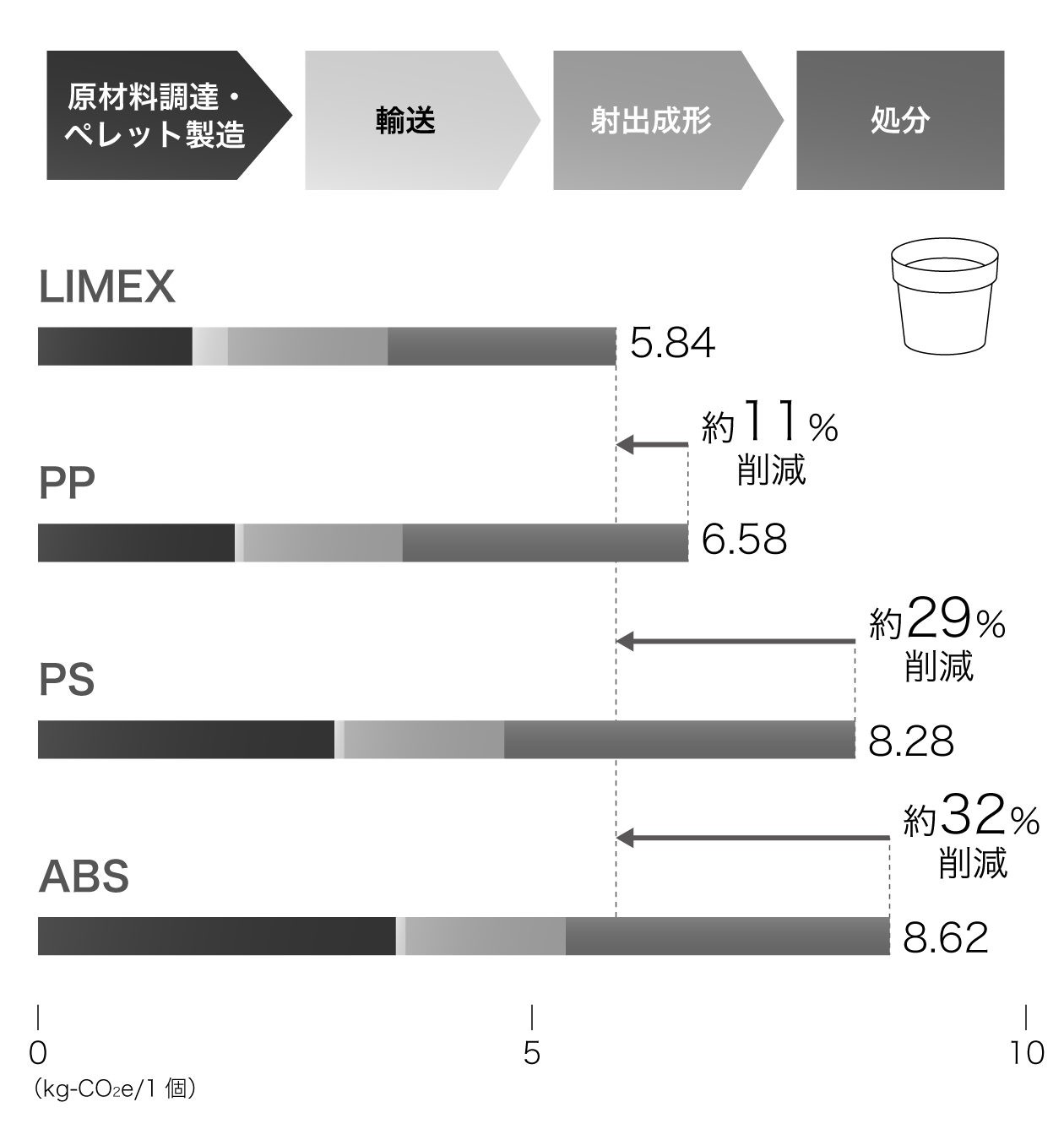

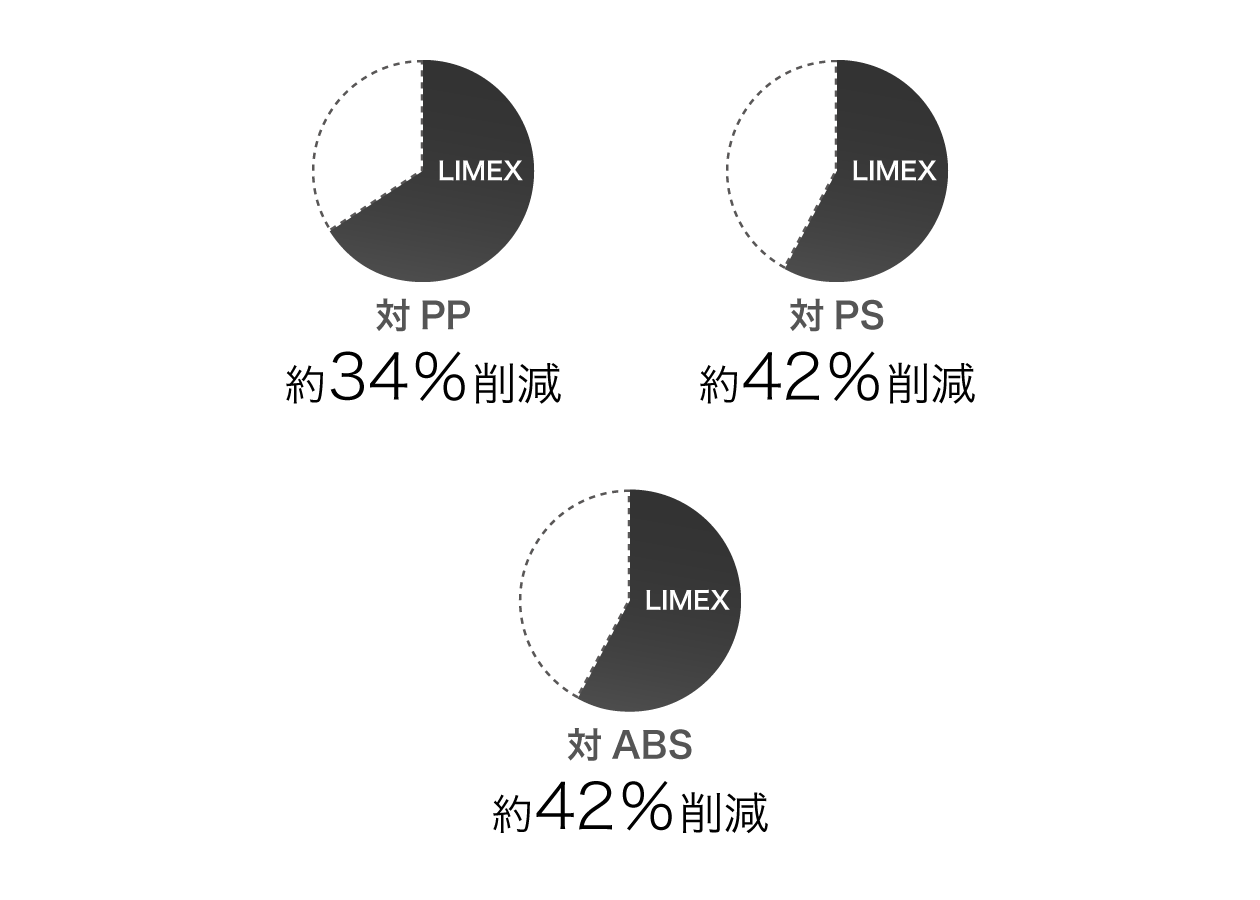

射出成形品

GHG排出量

• 機能単位:植木鉢1個(LIMEX製で1.51kg)

• スコープ:[原材料調達・ペレット製造]〜[射出成形]〜[輸送]〜[処分]

• 輸送:LIMEXのみ ベトナム→日本 の海上輸送を加味

• 成形:成形時の負荷はPPと同等と想定

• 処分:一般廃棄物として焼却を想定

• 算定年:2022年

石油由来プラスチック削減量

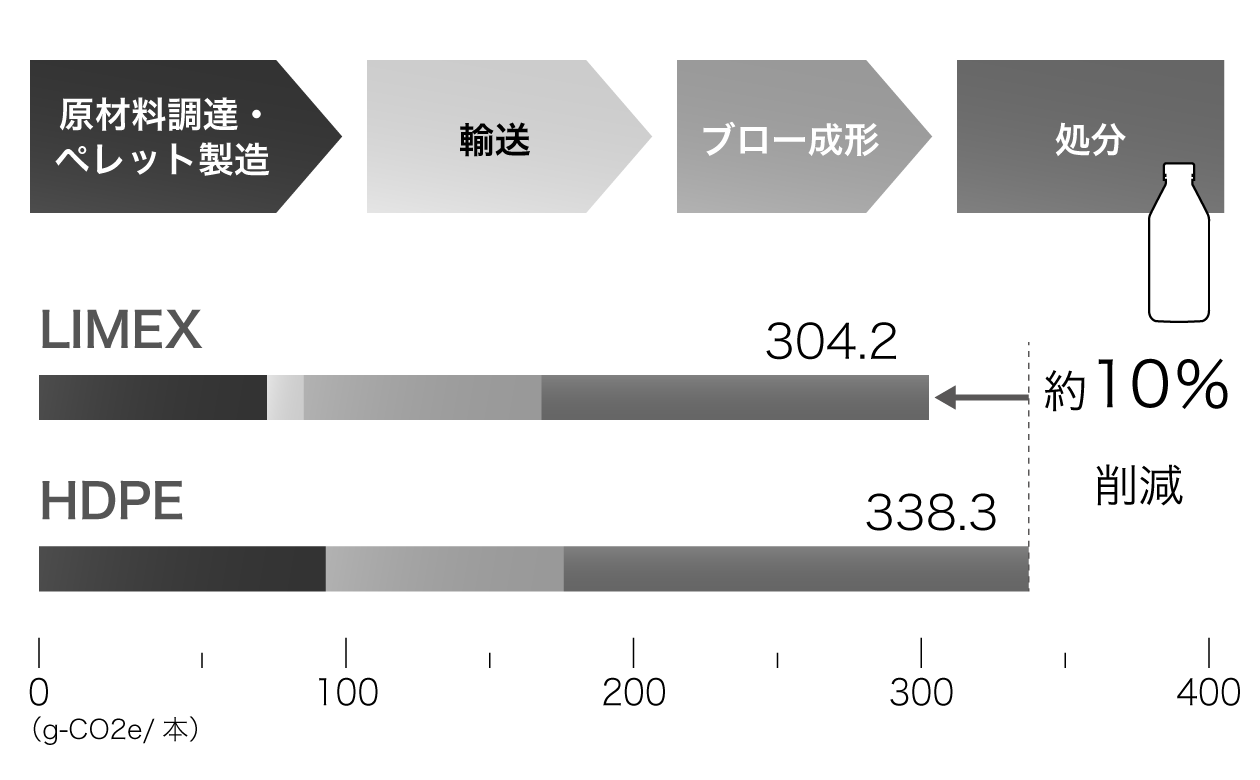

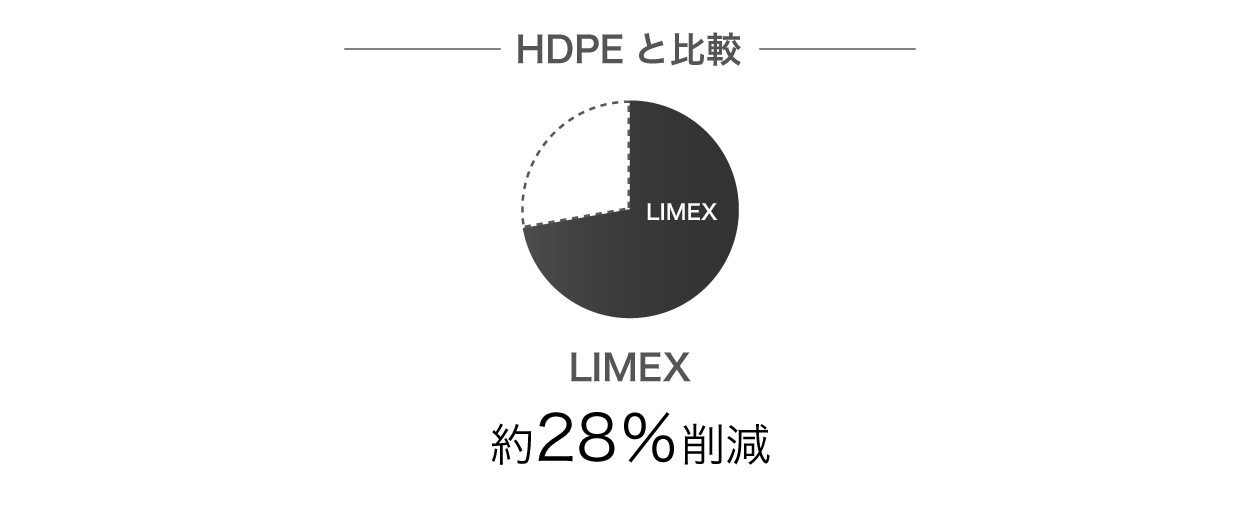

ブロー成形品

GHG排出量

• 機能単位:ボトル1本(LIMEX製:75g/本)

• スコープ:[ペレット調達・製造~ブロー成形~処分]

• 処分:一般廃棄物として焼却を想定

※ブロー成形の影響はHDPEを基準にLIMEXでも同等と想定

※サプライチェーンの要所は押さえ、簡略化したプロセスフローを評価

• 算定年:2023年

石油由来プラスチック削減量

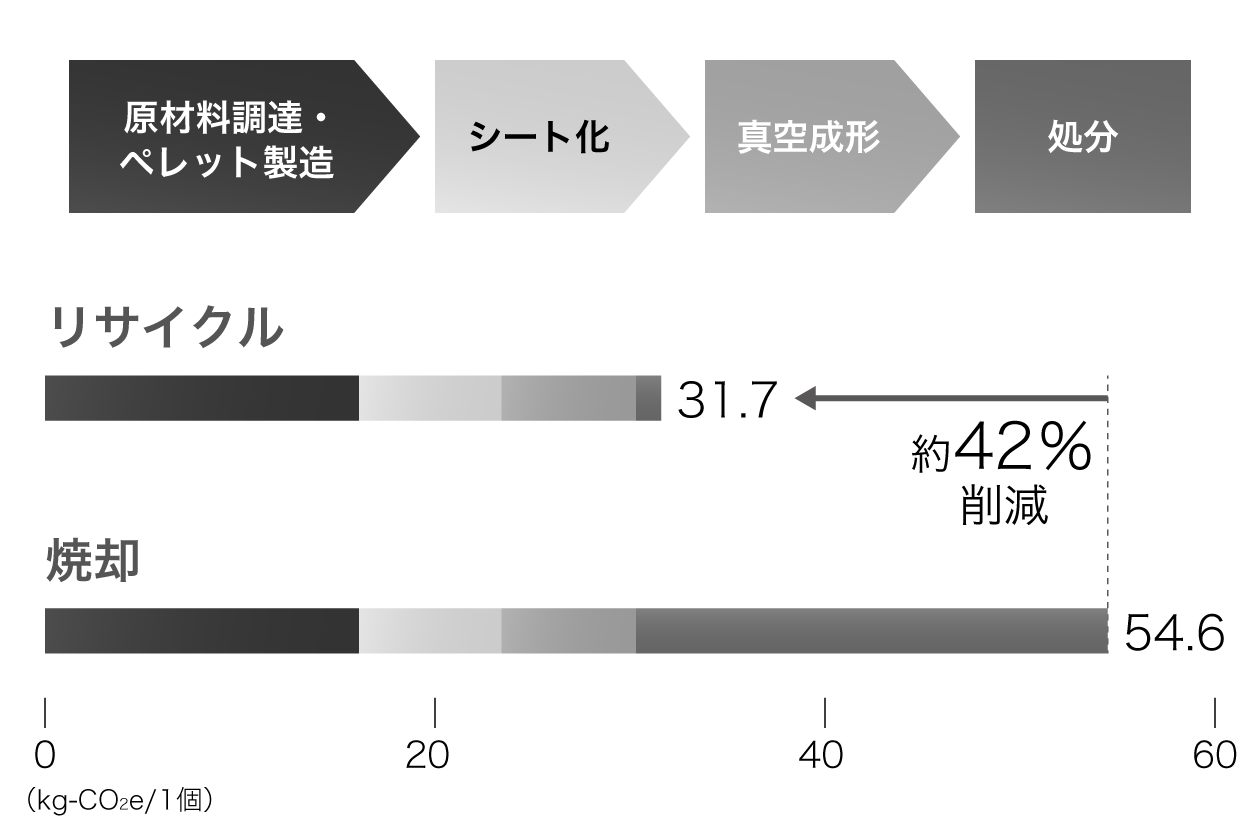

リサイクルによるGHG排出量の低減

LIMEX製品のライフサイクルを通じたGHG排出量は、焼却処分ではなくマテリアルリサイクルすることで大幅に削減することができます。TBMは、自社運営のリサイクルプラントを運営するなど、LIMEXの資源循環にも取り組んでいます。

GHG排出量

• 機能単位:飲料カップ1個(LIMEX製で14.4g)

• スコープ:[原材料調達・ペレット製造]〜[シート化]〜[真空成形]〜[処分]

• 処分:ベール化されることを想定

• 算定年:2022年