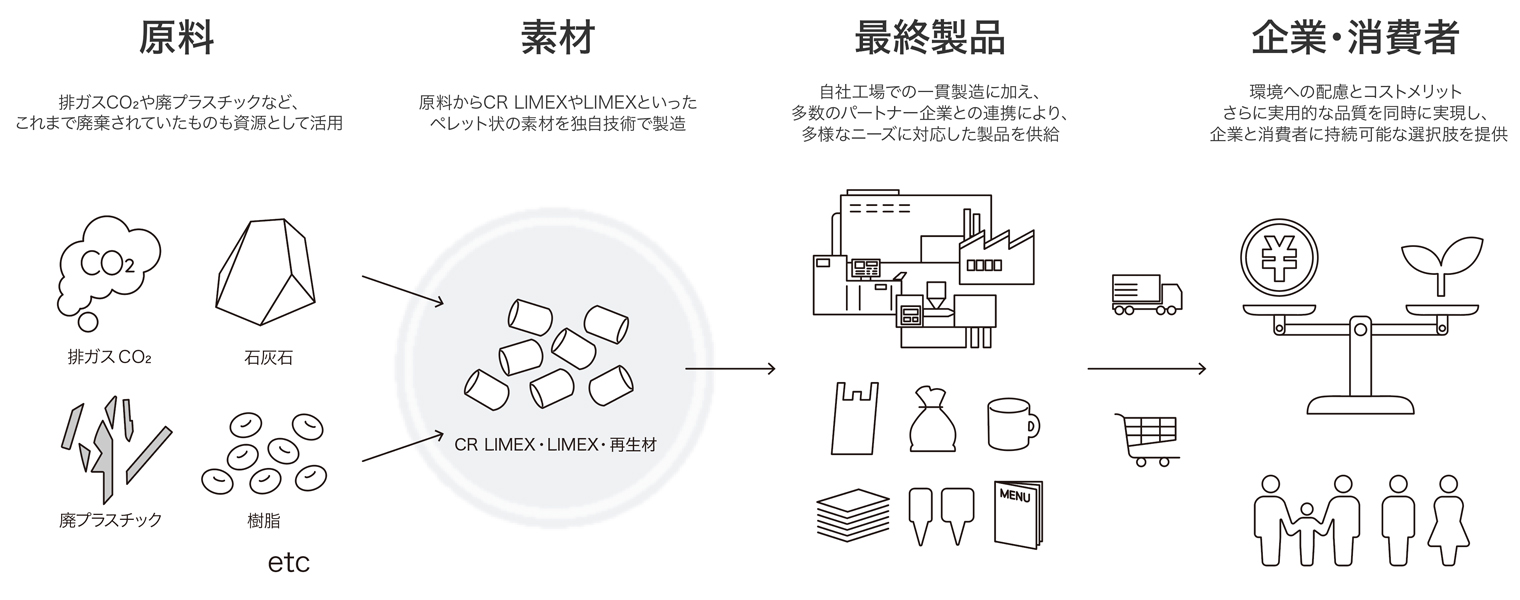

製品販売事業

環境素材を製品化し、

社会に実装する。

私たちが開発した環境配慮型素材(CR LIMEX, LIMEX, 再生材)を、エンドユーザーである企業や消費者が利用できる「最終製品」の形にしてお届けする、「社会実装の最前線を担う事業」です。自社での素材開発・製品製造で培った当社の深い技術知見と、成形・印刷・リサイクル等の500社を超える専門パートナーのノウハウを融合させ、環境性能だけではなく、実用的な品質と経済合理性(コスト)を高いレベルで両立させた製品を企画・開発しています。その価値が評価され、すでに10,000以上の企業や自治体等で採用され、社会全体のサステナビリティ推進に貢献しています。

事業を取り巻く環境と課題

石油由来プラスチックの使用規制の強化や、消費者の環境意識の高まりを受け、企業が調達・使用する製品の環境対応は、社会的責務となりつつあります。しかし、多くの企業は導入の過程で、現実的な課題に直面しています。従来の調達コストの不安定化に加え、多くの環境配慮型素材が伴う導入コストの上昇や、物性変化による品質懸念が、エンドユーザーの求める「環境性能の追求」と「実用的な品質・経済合理性」を同時に満たす上での高い障壁となっているためです。この社会的な需要ギャップを埋め、「実用的な品質と経済合理性を両立させた『環境配慮型の最終製品』」として安定的に供給することこそが、本事業が解決すべき中核的な課題です。

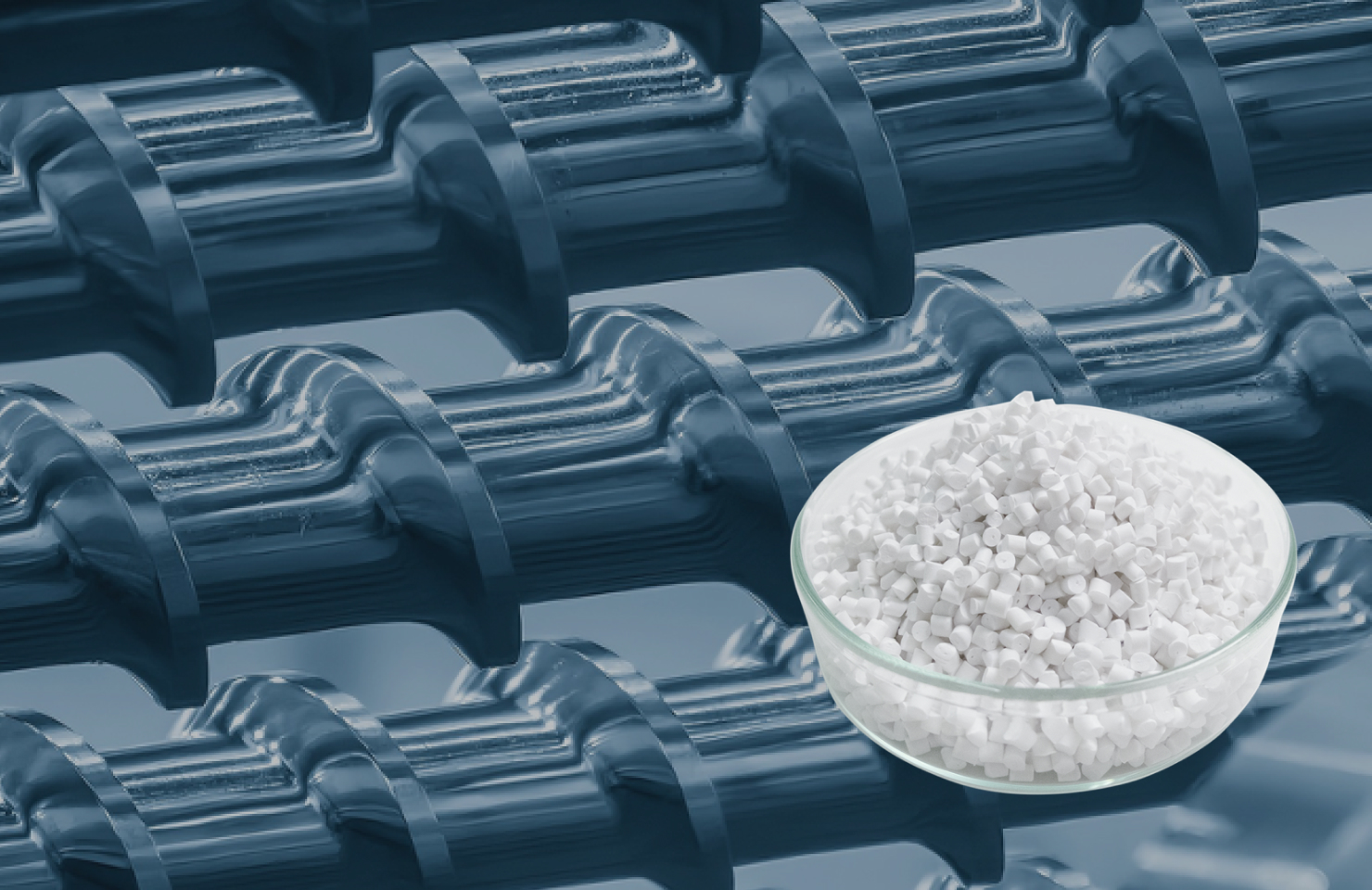

LIMEX Pellet 製品

プラスチック製品の代替として、環境性能と経済性を両立する実用的な製品

石灰石を原料とするLIMEXの特性を活かし、コンパウンド製品や袋製品など、石油由来プラスチック製品からの切り替え需要が高い分野に向けて、高品質な製品を提供します。

従来の石油由来プラスチック製品の品質・使いやすさを維持しながら、環境負荷と調達コストの削減を同時に実現し、企業のサステナビリティ推進と事業成長に貢献します。

製品名:パージ剤 (LIMEX Purge)

樹脂成形機のメンテナンス効率を高める業務用洗浄剤です。石灰石などの無機物を50%以上配合することで、高い洗浄力を発揮しつつ石油由来プラスチック使用量を削減します。短時間・少量での洗浄を実現し、生産現場のダウンタイム短縮と材料コスト削減に貢献します。自動車部品メーカー等のTier1企業様でも採用実績があります。

製品詳細はこちら

製品名:レジ袋・ショッパー

用途に合わせた最適な成分比率の調整により、必要な強度とコスト最適化を実現します。バイオプラスチックの配合等、企業の環境方針に合わせたカスタマイズが可能で、CO₂排出量削減にも寄与します。

導入事例:羽田空港

製品名:ゴミ袋

独自の加工技術による薄肉化・軽量化設計で、原料使用量そのものを削減します。従来のPE(ポリエチレン)製ゴミ袋と比較し、環境負荷低減とコスト抑制を同時に実現する、経済合理性の高い製品です。

導入事例:アパホテル、わらべや日洋、びっくりドンキー

製品名:不織布

従来のPP(ポリプロピレン)製スパンボンド不織布と比較し、石油由来プラスチック使用量を削減します。十分な強度と加工適性を保持しており、衛生・医療用途から農業資材、ショッピングバッグまで展開可能です。環境配慮型素材への切り替えによる企業ブランディングの向上にも貢献します。

導入事例:保険見直し本舗

シーラントフィルム

シーラントフィルム 食品容器

食品容器 化粧品容器

化粧品容器 ボトル

ボトル 建築資材

建築資材

LIMEX Sheet 製品販売

プラスチックフィルム・合成紙の代替となる、高付加価値シート製品

安価な石灰石を原料として使用することで、従来の石油由来プラスチックフィルムや合成紙と比較し、導入コストの削減を実現しました。またライフサイクル全体でのCO₂排出量を抑えられるため、環境経営への貢献も可能です。機能面では、既存品同等の耐水・耐候性を維持しつつ、優れた色の再現性と光拡散性を発揮します。屋外利用・高品質な印刷が求められる用途において、経済合理性と環境価値、実用的な機能性を兼ね備えた新たな選択肢を提示します。

製品名:電飾シート

高い光透過性と優れた光拡散性を両立し、どの角度から見ても鮮明で美しい発色を実現します。従来のプラスチック製フィルム(PP・塩ビ製)と、石油由来プラスチック使用量を削減しつつ、コストを抑制します。環境配慮と広告効果の最大化を同時に実現します。

導入事例:モスバーガー

製品名:園芸ラベル

国内での高いシェアが証明する、上質な質感と鮮明な印刷品質が、情報媒体としての商品の魅力を引き立てます。従来のプラスチック製ラベルに比べ、コストを抑えつつ、石油由来プラスチックの使用量とCO₂排出量も削減も実現します。

導入事例:DCM、Proven Winners

クリアファイル

クリアファイル タペストリー

タペストリー ポスター

ポスター 冊子

冊子 メニュー表・POP

メニュー表・POP ラミネートフリーシート

ラミネートフリーシート 名刺

名刺

採用企業・自治体数

LIMEX製品は、その環境性能と経済合理性が評価され、業種・規模を問わず10,000以上の企業や自治体で採用されています。

お問い合わせ

製品のお見積りや詳しい資料のご請求、導入に関するご不明点やご相談がございましたら、下記よりお気軽にお問い合わせください。

貴社の課題解決に向けた最適なプランをご提案します。