Press release

- LIMEX

TBM presents "Next-Generation LIMEX" using CCU technology at the Davos Meeting

Tokyo, January 19, 2024 – TBM presented "Next-Generation LIMEX" using CCU (Carbon Capture and Utilization) technology at the World Economic Forum annual meeting in Davos, eastern Switzerland (Davos Meeting, January 15-19, 2024).

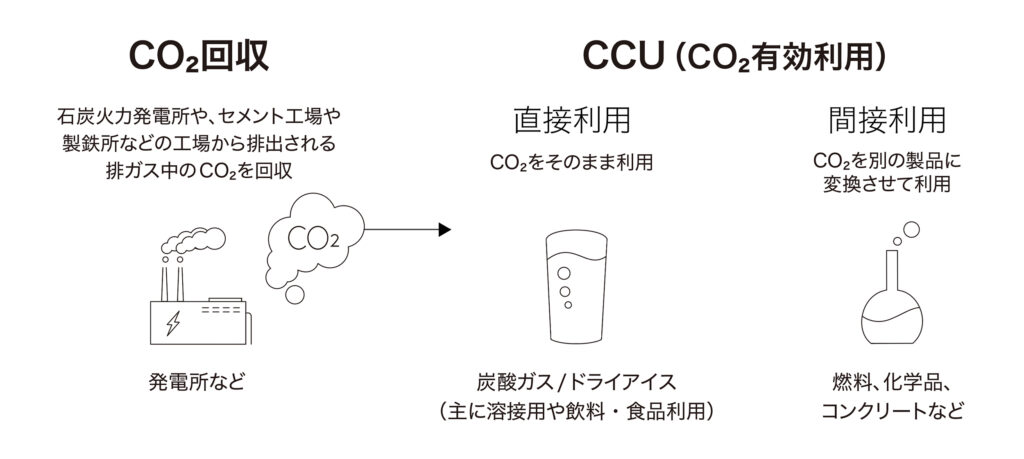

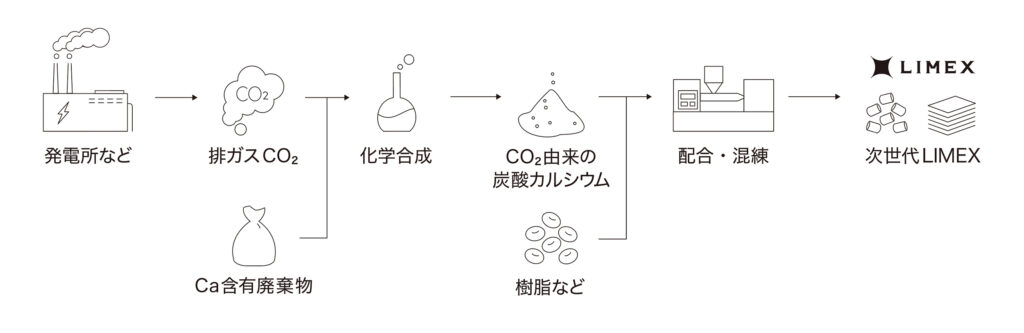

CCU, which captures emitted CO2 and reuses it as a variety of carbon compounds, is attracting attention globally as one of the most important technologies for reducing CO2 emissions into the atmosphere. The Next-Generation LIMEX uses calcium carbonate made from CO2 in emission gas from factories as raw material, instead of calcium carbonate derived from limestone. The calcium carbonate for Next-Generation LIMEX is chemically synthesized from CO2 and waste liquid from factories that contain calcium, such as concrete sludge and steel slag, through a process with low environmental impact. Next-Generation LIMEX is an environmentally friendly material that contributes to carbon neutrality.

*LIMEX is an inorganic filler-dispersion composite material containing more than 50% inorganic materials such as calcium carbonate.

Next-generation LIMEX websitehttps://tb-m.com/eng/business/limex2.0/

Background

Huge Impact of CCU on Decarbonization

According to the IEA forecast, CCUS (Carbon Capture, Usage and Storage), including CCU technology, is expected to contribute approximately 19% to reducing CO2 emissions from energy sources, placing it in the top three. CCU technology is expected to significantly contribute to creating a carbon-neutral society.*IEA “Energy Technology Perspectives 2020”

The Rapidly Growing Global Market for CCU Technology

ICEF forecasts that the market for products made from CO₂ using CCU technology could grow to $297.5 billion (about 40 trillion yen) in 2025 and $837 billion (about 120 trillion yen) in 2030.*The Innovation for Cool Earth Forum (ICEF); Carbon Dioxide Utilizaiton (CO2U) – ICEF ROADMAP 1.0、$1=140 yen。

Promotion of Carbon Neutral Technology by the Japanese Government

The Japanese government also established a "Carbon Recycling Roadmap" in 2023 to promote CCU further and achieve its carbon neutrality goal for 2050. The maximum amount of CO2 recycled by CCU technology in 2050 is estimated to be approximately 100-200 million tons.。

*Ministry of Economy, Trade and Industry, Agency for Natural Resources and Energy, "Carbon Recycle Road Map."

Overview of Next-Generation LIMEX

Over 10,000 companies and municipalities have already adopted limestone-based LIMEX as an alternative material for plastics that can reduce petroleum-based plastics and CO₂ emissions throughout its life cycle and an alternative material for paper that reduces water consumption.

Instead of calcium carbonate derived from limestone, the Next-Generation LIMEX contains calcium carbonate made from CO₂ emitted from industrial factories, chemically synthesized through a low-environmental-impact process, and is expected to be carbon-negative. In developing the Next-Generation LIMEX, TBM was supported by NEDO (New Energy and Industrial Technology Development Organization) and Tohoku University. As a member of the World Economic Forum Unicorn Community, the founder and CEO of TBM, Nobuyoshi Yamasaki, presented prototypes of the Next-Generation LIMEX products at the Davos Meeting 2024.

TBM will prepare for the mass production of the Next-Generation LIMEX and continue to improve the carbon footprint by using biomass-based resin and recycled resin for the binder instead of petroleum-derived resin.

Features

Optimization Technology of Calcium Carbonate Suitable for LIMEX

For the Next-Generation LIMEX, it is very important to design and control the particle size and shape of the calcium carbonate made by CCU technology to be optimal for LIMEX. Through the development of LIMEX, TBM already has more than 200 patents worldwide in more than 40 countries and a domestic patent for CCU-related technology, which is filed for international application.

Applicable for a Wide Range of Value-added Applications

Currently, cement and aggregates are the main applications for calcium carbonate made with CCU technology. Next-generation LIMEX can be used in various applications like limestone-based LIMEX, from industrial materials to daily consumer goods, such as industrial film, food packages, and labels.

Environmental Performance through CCU

Using calcium carbonate made by CCU technology, LIMEX can reduce petroleum-based plastic consumption and CO₂ emissions throughout its life cycle compared with plastic. Next-generation LIMEX can be recycled multiple times without releasing CO₂. Furthermore, using calcium-containing waste as a raw material for Next-generation LIMEX can contribute to the effective use of resources through recycling.

Brand Logo

The visual icon of the next-generation LIMEX represents an "X" and inherits the current LIMEX concept of holding unlimited possibilities. LIMEX's "LIME" will evolve from the meaning "LIMEstone" to "Low Impact Material for Earth." This material will incorporate new technologies to sustain a global environment where people can thrive.