素材開発事業

環境・社会課題を解決する、素材をつくる。

本事業は、気候変動対策とプラスチックごみ問題への対応が急務となる市場において、素材を扱う企業が直面する、環境規制対応と高品質で安定供給が可能な代替素材の確保という課題を解決します。具体的なソリューションとして、CO₂を回収・再利用した低炭素素材「CR LIMEX」、高付加価値原料としての「CR炭酸カルシウム」、石灰石を使用したプラスチック代替素材「LIMEX」、独自開発により物性の強化を実現した「再生材(PCR材)」という環境配慮型素材の開発・製造・販売を行っています。CO₂の長期固定化を実現するCR LIMEXは内装材やエクステリア等の建築資材へ、また脱炭素化や資源循環に関する法整備が進む自動車や家電、包装産業等へ再生材やLIMEXを展開。当素材は、サプライチェーン全体の環境負荷低減を可能にし、環境配慮が求められる市場での確固たる競争優位性を築きます。さらに、既存の成形機での製品化が可能な導入障壁の低さと、世界で豊富に存在し、枯渇リスクの低い石灰石を原料に使用することで、安定供給性および価格安定性を両立し、継続的な利用が可能です。当社独自の技術開発力が、エンドユーザーが求める品質を担保しており、この素材に関する技術力と知見に基づく手厚いサポート体制をもとに、企業の脱炭素経営と持続可能なものづくりを支援します。

事業を取り巻く環境と課題

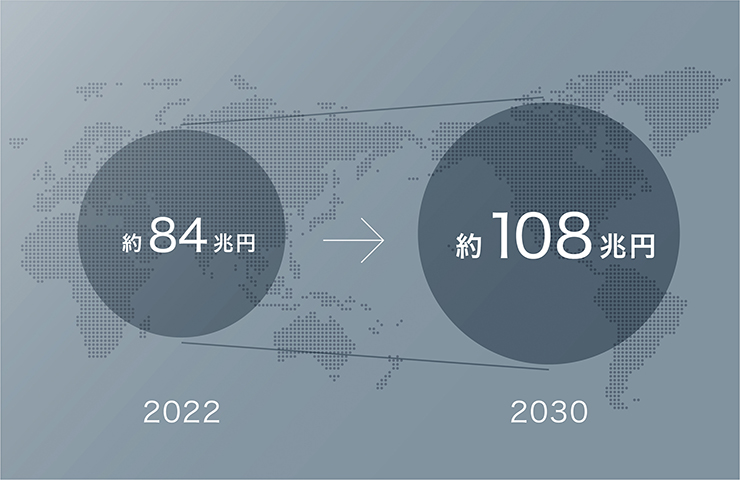

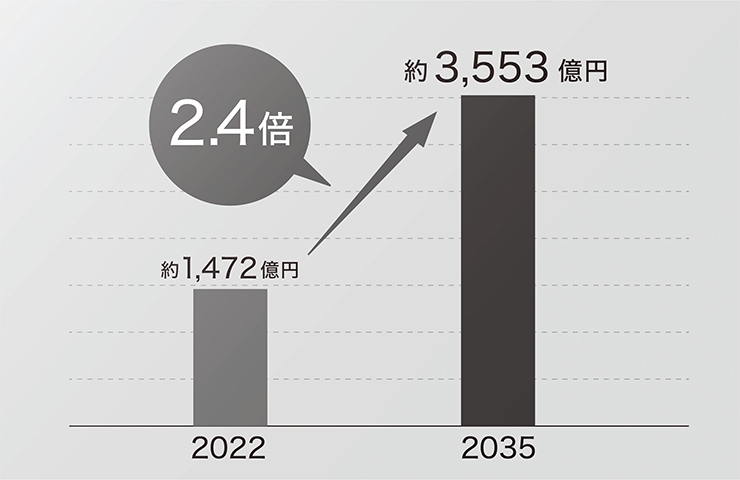

深刻化する気候変動への対策として、国内外で石油由来プラスチックの使用規制や自動車・家電の分野で再生材の利用を義務化する法整備が進んでおり、企業はサプライチェーン全体でのCO₂排出削減と石油由来プラスチック依存からの脱却という経営課題に迫られています。一方で、グローバルではプラスチックの市場は大きく成長しています。素材を取り巻くあらゆる分野で環境負荷を低減する素材の需要が高まっています。

世界のプラスチック市場規模

日本の再生プラスチック市場規模

一方、従来の環境配慮型素材は、スイッチングコストを含む価格負担の大きさや安定供給性の脆弱さ、さらには素材品質に対する懸念など、導入の障壁となり得る複数の課題を内包しています。これに対し、当社の素材は、世界に豊富に存在する石灰石(炭酸カルシウム)を原料とする素材特性と、強固なグローバルサプライチェーンを最大限に活用することにより、高い安定供給性と価格安定性を実現。加えて、多くの企業・自治体で導入実績が存在する当社の素材は、その品質および信頼性の両面において評価を獲得しており、環境価値の提供にとどまらず、企業の持続可能な経営を支える素材ソリューションとして機能します。

採用企業・自治体数

当社の素材はすでにCOPやG20、ダボス会議など国際的な会議で紹介されているほか、国内外で環境規制対応や品質維持といった課題のソリューションとして10,000以上の企業や自治体での採用実績を有します。また、当社が実施する環境負荷低減効果の可視化(LCA)は、「SuMPO/Internal-PCR承認制度」による第三者認証を取得しているため、その算定結果には高い信頼性が担保されています。この客観的根拠に基づき、LIMEX採用企業は、その環境価値や脱炭素への貢献をステークホルダーに対して高い透明性をもって発信し、グリーンウォッシュリスクを排した、堅実な企業価値向上を実現しています。

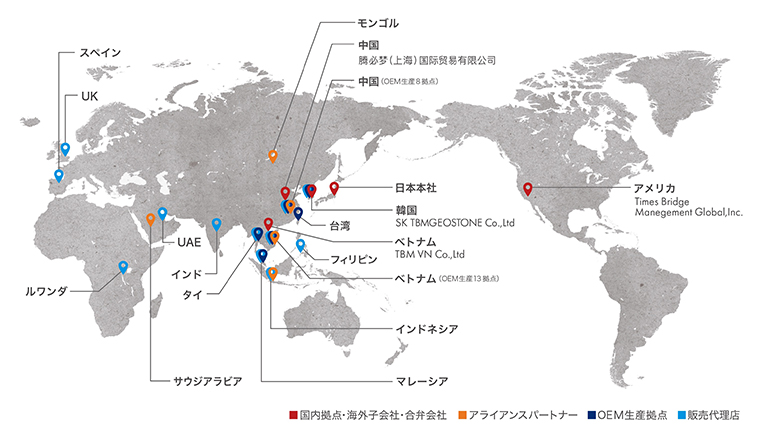

グローバル展開

当社は、地球規模の複雑な課題に対応するため、環境配慮型素材ソリューションの安定供給体制を構築しています。ベトナム、中国の現地法人を戦略的拠点とし、強固なサプライチェーンとグローバル販売代理店網を強化することで、世界のあらゆる地域への迅速な供給を実現します。

素材の知財戦略

当社は2014年の国内特許取得以来、世界50ヵ国以上でLIMEX関連特許250件超を権利化し、経済産業省「知財功労賞」等の評価も得てきました。これらの知財ポートフォリオにより、技術的な参入障壁と競争優位が形成され、長期の安定供給と継続的な改良が可能となることで、安心して導入いただける素材となっています。

- 特許取得国数

- 52ヵ国

- 特許取得件数*

- 約250件

*2025年10月時点、特許登録済みの件数

*国内外を含む累計件数

低炭素素材 CR LIMEX

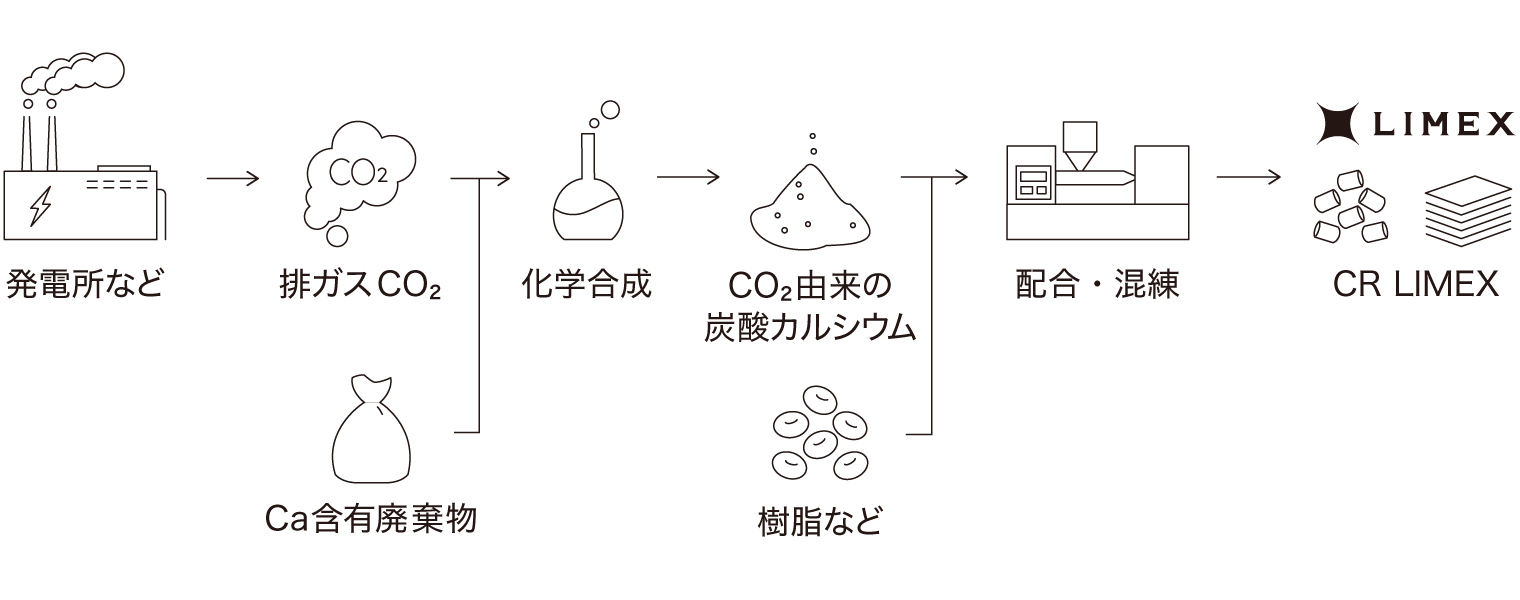

CR LIMEXは、カーボンリサイクル技術を実用化し、工場の排出ガス由来のCO₂とカルシウム含有廃棄物を化学合成することで世界に先駆けて開発された革新的な低炭素素材です。CO₂由来の炭酸カルシウムを原料とするプラスチック代替素材として、新たな価値を創出します。当素材は、素材自体にCO₂を安定的に吸収・固定することで、CO₂排出量を抑制し、カーボンニュートラルに貢献します。さらに炭酸カルシウムに配合・混錬する樹脂部分に再生プラスチックを組み合わせることも可能であり、企業の脱炭素経営と環境負荷低減に大きく貢献する素材です。環境価値に加え、既存設備での成形性、耐久性、意匠性などの優れた実用性能を両立。内装材やエクステリア等の建築資材をはじめとする高付加価値市場において、採用を拡大していきます。

CR LIMEXの製造方法

特徴

排ガス由来のCO₂の固定化を実現

排ガス由来のCO₂を化学合成したCR炭酸カルシウムとして素材に約25%*含有。

高温で焼却されない限り、長期的にCO₂を固定化するため、特に、建築内装材や土木資材といった耐用年数の長い製品ではCO₂の固定の効果が大きく、当該製品での採用を進めていきます。

*CO₂の比率は、今後のグレード追加や変更等により変動する可能性があります。

再生プラスチックの活用により、

資源循環を促進

CR炭酸カルシウムに配合・混錬する副原料に再生プラスチックを使用することで、CO₂の有効活用とともにプラスチックの資源循環にも貢献します。また、CR炭酸カルシウムの原料となるカルシウム源も工場廃材などのカルシウム含有廃棄物を活用しています。

CO₂排出量と石油由来プラスチック使用量を削減

石油由来プラスチックをCR LIMEXに置き換えることで、CO₂排出量と石油由来プラスチック使用量を約34%*削減し、脱炭素・資源保全に寄与します。

*推定に基づく概算値であり、保証値ではありません。製造条件等に応じて、数値変更の可能性があります。また、温室効果ガス(GHG)排出量や石油由来プラスチックの使用量は、今後のグレード追加や変更等により変動する可能性があります。

独自の炭酸カルシウム制御技術による

安定した成形性

LIMEXの開発で培った炭酸カルシウム制御技術を活用することで、CO₂を固定化したCR LIMEXであっても既存の成形設備での安定した製品化が可能です。

幅広く、付加価値の高いCR LIMEXの用途

カーボンリサイクル技術を活用した炭酸カルシウムの用途は、従来はコンクリートやセメント、骨材が主に考えられていました。 CR LIMEXは、従来のLIMEXで培った鉱物由来の炭酸カルシウムを高充填する技術や制御・混錬技術を活用して、内装材やエクステリア等の建築資材などの高付加価値用途に使用することが可能です。

高付加価値原料としてのCR炭酸カルシウムの開発、販売

当社では、同様のプロセスで排ガス由来のCO₂を原料として生成されるCR炭酸カルシウムの開発も行っています。炭酸カルシウムが原料であるLIMEXで培った粒径・形態制御技術の知見を応用し、用途に応じて特性をカスタマイズできる高付加価値原料です。既に建材メーカー等でも実用化されており、従来の重質炭酸カルシウムの代替原料として幅広い用途で活用することが可能です。

低炭素素材 LIMEX

LIMEX(ライメックス)は、プラスチックの代替となる、炭酸カルシウム(石灰石)などの無機物を50%以上含む環境配慮型素材です。石油由来プラスチックと比較して、石油由来プラスチックの使用量や製品のライフサイクルで生じるCO₂の排出量の削減が可能です。原料である石灰石は、資源が少ない日本でもほぼ100%自給自足が出来るほど豊富に存在する資源であり、石油由来プラスチックの一部を石灰石で置き換えることにより、素材の環境負荷低減に加え、安定供給性や価格安定性の向上につながります。LIMEXは、国内の自社工場での生産に加え、国内外のパートナーと連携したファブレスモデルによる素材のOEM生産が可能です。既存の成形機や印刷機での製品化が可能であるという導入障壁の低さから、今では袋や容器包装、建材、不織布、印刷物、販促物等の製品用途で10,000を超える企業や自治体に採用されています。

特徴

環境負荷低減

LIMEXは、原料に石灰石を使用することで、プラスチック代替素材として、石油由来プラスチックの使用量と製品ライフサイクル全体でのCO₂排出量を削減します。また、その削減量はLCA(ライフサイクルアセスメント)を通しての可視化が可能です。

価格安定性と価格競争力

安価で資源として豊富に存在する石灰石を原料に使用していることで、供給安定性と価格安定性が高いです。他の環境配慮型素材と比較しても高い価格競争力を有しています。

OEM生産が可能、ファブレスモデルでの展開

LIMEXは押出成形、インフレーション成形、真空成形、射出成形等の多様な成形方法に対応しています。また、LIMEXは、その製造に専用の設備を必要とせず、自社工場だけでなく既存の成形機が使用できるため、製造委託先でのOEM生産が可能です。

用途

プラスチック代替:LIMEX Pellet

石油由来プラスチックの代替となるペレット状(コンパウンド)のLIMEXです。インフレーション成形、押出成形、射出成形、真空成形などの多様な成形方法に対応しており、袋や容器包装、不織布などに幅広く活用されています。

合成紙代替:LIMEX Sheet

合成紙の代替として使用されるシート状のLIMEXです。環境性能に加え、耐水性・耐久性にも優れています。既存の印刷・加工設備を活用して、電飾シートや屋外広告、園芸ラベルなど、印刷物から産業資材まで幅広く活用されています。

石灰石について

石灰石は資源に乏しい日本でも自給自足できる数少ない資源であり、供給安定性と価格安定性が高いです。世界各地に豊富に存在するため、地産地消モデルによるコンパクトなサプライチェーン構築も可能です。さらに、石油由来プラスチックであるポリプロピレンと比較して、GHG(温室効果ガス)排出量を原材料調達段階で約83%*1、処分(焼却)時においても約43%*2抑制できるなど、製品のライフサイクル全体を通じて環境負荷低減に貢献する資源です*3。

*1 石灰石単体ではPPと同様の機能を果たさない点に留意。輸送:10トントラックで500 km輸送することを想定

*2 石灰石単体ではPPと同様の機能を果たさない点に留意。処分方法:一般廃棄物として焼却した場合を想定(焼却炉の運用と材料由来の発生CO₂を加味)

*3 TBMによる概算。製造条件等によって変動の可能性あり。参考値であり保証値ではありません。主な参照DB: LCIデータベース IDEA version 3.2.0 (2022/04/15) 国⽴研究開発法⼈産業技術総合研究所安全科学研究部⾨IDEAラボ|影響評価⼿法:Climate change IPCC 2013 GWP 100a

再生材(容器包装リサイクル材)

当社は、国内最大級の規模を誇る横須賀サーキュラー工場にて、家庭由来の容器包装プラスチックを原料とした容器包装リサイクル材(容リ材)を製造しています。独自のR&D機能と素材開発技術を活かし、従来の容リ材が抱えていた臭気や物性低下といった課題を解決するとともに、当社の容リ材はPIR(産業廃棄物由来プラスチック)やバージン材と同等以上の強度を有した再生材も供給が可能、品質に妥協することなく容リ材を使用することが可能です。さらに、こうした品質特性に加え、PIRやバージン材と比較して高い価格競争力も有しており、CO₂排出量の削減に資する優れた環境性能も備えているなど、再生材の導入障壁を大きく下げます。

横須賀サーキュラー工場

- ・家庭由来の汎⽤プラスチックとLIMEXを⾃動選別し再⽣利⽤する世界初のプラント

- ・2022年11月に竣工

- ・年間約12,000tの処理実績

特徴

安定供給が可能

年間約4万トンの処理能力、年間約2万4000トンの再生ペレットの生産能力を背景に、容リ材の安定供給を実現します。

PCRである容リ材の提供と開発技術

容リ材は、家庭から排出される容器包装プラスチックを原料とした再生材(PCR)です。品質が安定し価格・調達難易度が高いPIR(産業廃棄物由来プラスチック)と比較すると、容リ材は価格面で優位がある一方、臭気や物性低下といった課題を有します。当社は、LIMEXで培った素材開発技術とR&D機能により、PCR材特有の課題を解決。顧客の製品用途に応じた処方開発も可能です。

PIRやバージン材と同等以上の強度と価格優位性

当社の素材開発技術と独自処方により、PCRでありながらPIRやバージン材と同等以上の強度の容リ材を開発。バージン材に対して高い価格競争力を持ちます。同時に、バージン材と比較して、容リ材1kgあたり最大6.43kg(最大61%相当)のCO₂排出量を削減します。

*保証値ではありません。データ取得状況等に応じて、数値変更の可能性があります。計算やデータ収集方法が異なるため、他社製品とは比較できません。

取り扱いラインアップ

当社では製品・成形メーカー等の“再生材等を利用して製品を製造する企業”と廃プラ排出企業・リサイクラー・コンパウンダー等の“再生材等を販売する企業”をつなぎ、再生材の調達を支援するプラットフォーム「Maar 再生材調達」を運営しています。上記以外の素材をお求めの場合は「Maar 再生材調達」をご確認ください。

詳しくはこちら用途

一般的な容リ材利用製品

お問い合わせ

素材のお見積りや詳しい資料のご請求、導入に関するご不明点やご相談がございましたら、

下記よりお気軽にお問い合わせください。